Qtj4-25 Semi Automatic Concrete Block Making Machine

Shandong Shiyue Intelligent Machinery Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

- Capacity:5800 Pieces

- Worker:1-3 Workers

Base Info

- Model NO.:QTJ4-25

- Pallets Size:850*450mm

- Shaping Cycle:25s

- Total Weight:4t

- Motor:Siemens Motor or ABB Motor

- Mixer:Jq500 Concrete Mixer

- Raw Material:Concrete, Sand,Cement, Fly Ash, Lime, Gypsum,etc.

- Products:Solid,Paver,Hollow etc

- Products Name:Qtj4-25 Cement Block Making Machine

- Transport Package:Nude Package

- Specification:3060*1730*2580mm

- Trademark:SHIYUE

- Origin:Shandong Province, China

- HS Code:8474802000

- Production Capacity:5000 Sets

Description

Model

QTJ4-25

Dimension of host machine

3060*1730*2580mm

Total Weight

4T

Host Machine Power

14.9KW

Cycle Time

25s

Pallet Size

850x450mm

Vibration force

45KN

Belt conveyor

8m

Mixer

JQ500 mixer

Block height

40-280mm

Workshop area(L*W*H)

10000*4000*3000mm

Test pressure

16Mpa/cm2

Machine Pictures

Productivity

Size(LxWxH)mm

Pcs/Mold

Pcs/hr

Pcs/8Hr

400X150X200

5

600

4800

400X200X200

4

480

3840

400X100X200

7

840

6720

400X250X200

3

360

2880

240X115X53

24

2880

23040

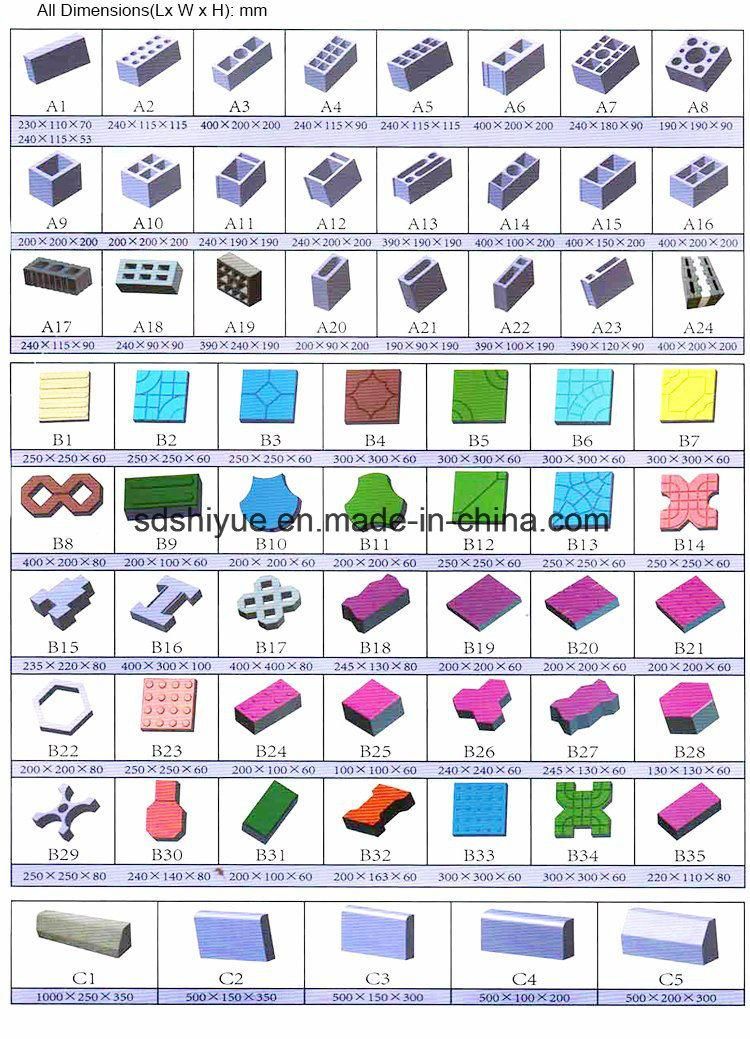

Block sample

Shipping and delivery

1. The whole brick machine production line equipment is mainly the full container sea shipping,

2. Brick machine equipments finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift,

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.

Our service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of build factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material,

capacity and the size of brick)

(3) Welcome to visit our factory and production line anytime

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side.

(2) Set up, fix,and operate

(3) Will not stop training the operator until they are satisfied at clients side.

(4) 24 hours service

(5) Recall clients regularly ,get feedback in time,keep well communication with each other.

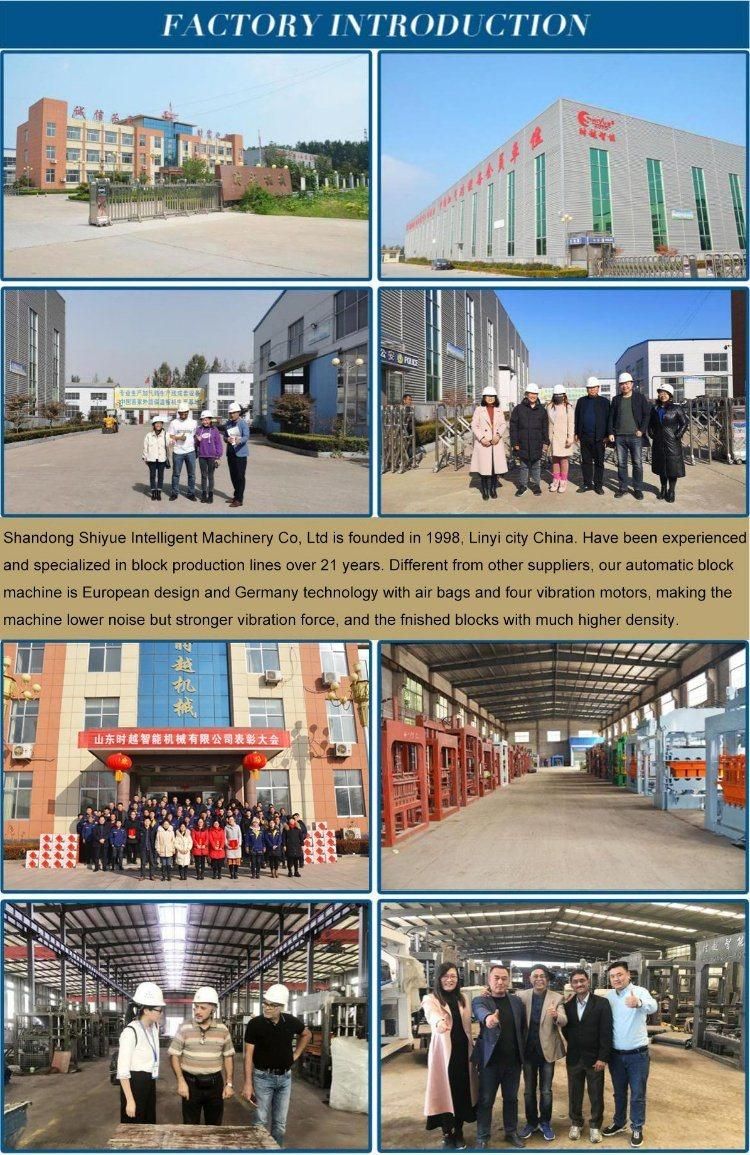

Our factory

1.Question:Does the machine could change mold?

Answer:Yes,this machine could change different kinds of mold.The machine could produce interlock, paver size depending on your local requirements.

2.Question:What is the electric voltage and rate?

Answer:Our local electric voltage is 380v, 3phase, 50hertz, the electricl voltage can be revised according to local situation.

3.Question:How about the service life of this machine?

Answer:This machine could work for about 6-10 years if your side maintain well.

4.Question:What's your machine warrenty?

Answer:12 months guarantee,we send more spare parts for you when shipping machine to you.

5.Question: The mode of transportation.

Answer: by sea, by land or by rail according to customer local need