Cheaper Price Grinding Ball Mill for Cement Powder Grinding

Xinxiang Great Wall Machinery Co., Ltd.- Application:Construction, Mineral Operation

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Feeding Granularit:≤25mm

- Advantages:Energy-Saving

Base Info

- Model NO.:Cement Powder Ball Mill

- Host Machine:Cement Ball Mill

- Capacity:100,000-1,500,000 Tons,Year

- Transport Package:Transport Package

- Specification:20-380t,h

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:15-250t,H

Description

Basic Info.

Model NO. Cement Powder Ball Mill Host Machine Cement Ball Mill Capacity 100,000-1,500,000 Tons/Year Transport Package Transport Package Specification 20-380t/h Trademark CHAENG Origin Henan Production Capacity 15-250t/HProduct Description

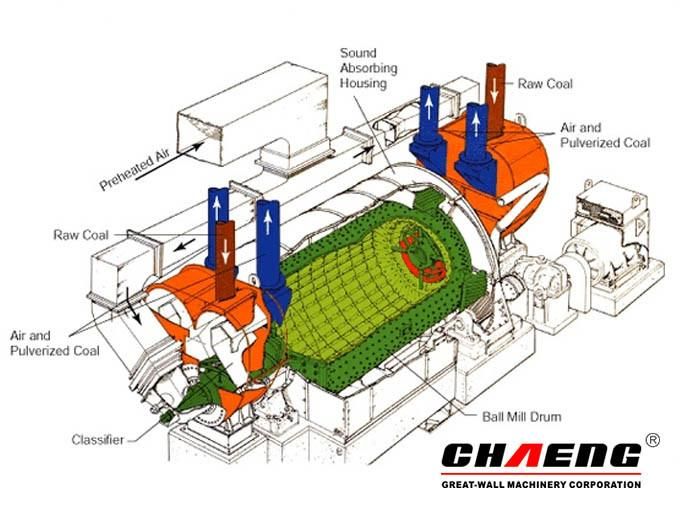

IntroductionThe cement mill is key equipment for the grinding process of the cement clinker after the crushing process of it. It is mainly used in the cement silicate product industry. After long term design and manufacture of the cement mill, our company now has series of cement mill with various specifications to meet with different requirement from our customers.

Ball mill features:

1.The machine is made up of feeding part, discharging part, gyre part, transmission part (reducer, small transmission gear, motor, and electrical controller) and so on.

2. The hollow axis adopts the cast steel and the lining can be replaced. The big rotary gear is forged from cast rolling gears.

3. The barrel body is inlaid with wearable plates.

4. The machine runs steadily and efficiently.

Features

1. Ball mill advantages

2. Milling efficiency

3. Mechanically simple design

4. Competitive capital cost

5. Capacity to operate continuously at full load power draw

6. Low rotational impeller speed with shallow charge depth providing reduced abrasion of impeller and body liner coverings

Process Description

The cylinder will rotate by the transmission device. Due to the inertial centrifugal force, the steel balls will stick on the liner plate and rotate with the cylinder together. When the steel balls come to a certain height, it will fall down by gravity and impact the raw material. And the repeated going-up, falling down, slide and roll of the steel balls can grind the raw material together with the liner plates.

Our service

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers' request and budget, our experts make efficient, reliable solutions. Following customers' order we produce strictly, what's more, before placing the order every customer has the chance to visit XinXiang Great Wall (Chaeng) working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers' plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of XinXiang Great Wall (Chaeng), they are now strategically located home and abroad, working for our customers.