-

Small Mini Widely Use Activated Lime Anthracite Shaft Vertical Kiln Machine

Overview Product DescriptionProduct ParametersPackaging & ShippingCompany ProfileOur ProductCertificationsOur AdvantagesFAQ1.Whyus?Weprovideprofessionalindustrialfurnaceandindustrialdesignascustomerorder.2.Howisthequalityofyourproducts?Ourproductsaremanufacturedstrictlyaccordi

-

Cnm 40mm to 200mm Post Tension Corrugated Duct Machine

Producing Metal Duct Spee13.5m/min For 35 to 58mm DiameterMetal Duct(Adjustable)12m/min For 60 to 85mm Diameter Metal Duct(Adjustable)11m/min For90 to 115mm Metal Duct(Adjustable)10/min For Diameter Of 120 to 135mm Metal Duct(Adjustable)VoltageThree Phase, 380V, 50HZ/ Single Phase, 220V, 50HZProduct

-

Electric Concrete Pole Steel Mould for Concrete Pole Production Line

Basic Info. Model NO. 6-25m

-

Automatic Expanded Mesh Machine (SHA033)

Basic Info. Model NO. SHA033

-

50000cbm Capaciy Particle Board Producing Line

Electric control systemG1Electric control forsanding section1G2Electric control formain linePLC model:Simens1Full setsBrief introduction:Company brandJINGYUANMInimum of quantity1x20GPDelivery timeWithin 15 days after got your depositShipping portQingdao and LianyungangCompany locationOur company is

-

High-Pressure Laminated Plywood Coarsing Machinery

MODEL NO .JY conjoined fixed thickness A typeJY conjoined fixed thickness B typeThe processing thickness2.5~80mm2.5~80mmMachining width40~1300mm40~1300mm1#Abrasive belt linear velocity18m/s18m/s2#Abrasive belt linear velocity16m/s16m/sFeeding speed0~100m&

-

Manufacturing Construction Company Lime/Cement/Limestone Plant Vertical Kiln

Overview Product DescriptionProduct ParametersPackaging & ShippingCompany ProfileOur ProductCertificationsOur AdvantagesFAQ1.Whyus?Weprovideprofessionalindustrialfurnaceandindustrialdesignascustomerorder.2.Howisthequalityofyourproducts?Ourproductsaremanufacturedstrictlyaccordi

-

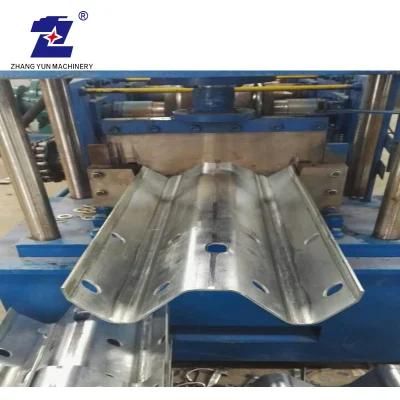

Highway Guardrail Profiles Plate Roll Forming Machine

Basic Info. Model NO. ZY-GY180

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd.

-

Elevator Hollow Guide Rail Production Line Cold Roll Forming Machine

Electrical control systemPLC Automatic Control SystemFAQ1.Q: Are you manufacturer or trading company?A: We are manufacture and trading company.2.Q:What info you need before you make the proposal?A:The pipe diameter and thickness range which you need or the profile drawings, material information, you

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd.

-

Environmental Friendly Metallurgy Lime Kiln Mining Kiln Lime Sleeve Kiln

Overview Product DescriptionProduct ParametersCapacity(t/d)Effective VolumeEffective HeightEffective SectionLimestone SizeHeat ConsumptionCaOActivity(m3)(m)Dia.(m)(mm)(kJ/kg)(%)(mL)1009820Ø2.530~60/40~80<4600>90>30012014120Ø3.030~60/40~80<4600>90>30