-

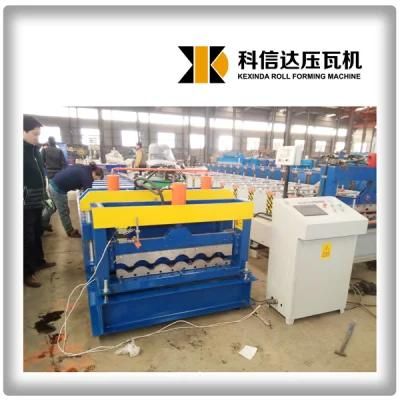

Siding Panel Wall Sheet Decorative Board Roll Forming Machine Line

Main parameters of siding panel wall sheet decorative board roll forming machine line1Suitable to processColor steel plate, galvanized sheet,aluminum coils and etc.2Width of the feeding materialas customer need3Roller station18 rows4Thickness of feeding material0.3-0.8mm5Productivity10-15m/min6Rolle

-

The Manufactured Products Can Replace Traditional Construction Methods Fiber Cement Board Equipment

Basic Info. Model NO. AM1728

-

Mineral Fiber Board Fibre Cement Sheet Machinery Plant Production Line

Basic Info. Model NO. HM Cu

-

Various Thicknesses Change According to Customer Requirements Cement Fiber Board Machine

Basic Info. Model NO. AM1728

-

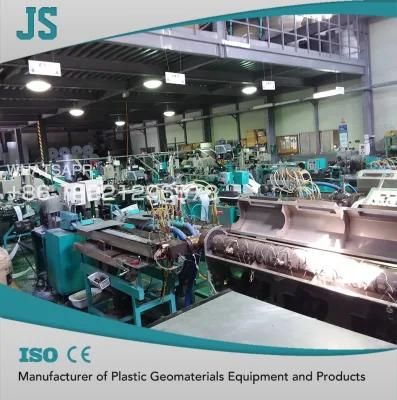

PVD Drainage Panel Making Machine

Basic Info. Model NO. JS-PVD1200

-

Go to Local Production Parts to Reduce Costs for Customers Fiber Cement Board Machine

Basic Info. Model NO. AM1732

-

Fiber Cement Board Machinery Production Line

Basic Info. Model NO. HM Cu

-

Aluminium Composite Panel Production Line

No.Main parameter for Aluminium Composite Panel Production Line1Suitable to processGalvanized/Aluminum/Color steel sheet2Width of plate1250mm3Thickness of plate0.3-0.8mm4RollersHigh grade 45# steel, with hard chrome plating5Forming steps166Sprocket chain1.5 inch7Pump station power4kw8Shaft75mm, high

-

Ibr Roof Sheet Panel Cold Roll Forming Machine

Our main products are: Steel-drum production line, Steel drum, BH-240/BH-120 Arch sheet roll forming machine, Ultimate Building Machine, Screw-jointed Equipment, Span Arch Sheet Project, UBM Building, Screw-jointed Project, KR 18 Roll Forming