Automatic Retaining Block Brick Paver Block Concrete Brick Making Machine Construction Equipment

Quanzhou Hawen Machinery Co., Ltd.- Certification:ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

- Pallet Size:980X680mm

- After Sales Service:Engineer Available to Overseas

Base Info

- Model NO.:QT6-15

- Retaining Block Size:400X250X305mm

- Warranty:One Yeear After Installation

- Vibration:Motor Vibration

- Working Method:Automatic

- Qty. Per Mould:4PCS Per Mould for Retaining Block

- Transport Package:Standard Ocean Packing

- Trademark:HAWEN

- Origin:China

- HS Code:8474809090

- Production Capacity:300 Sets, Year

Description

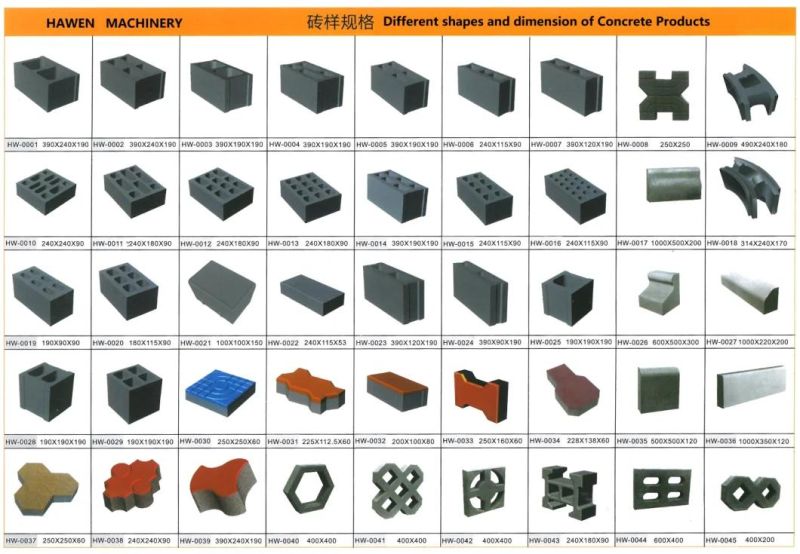

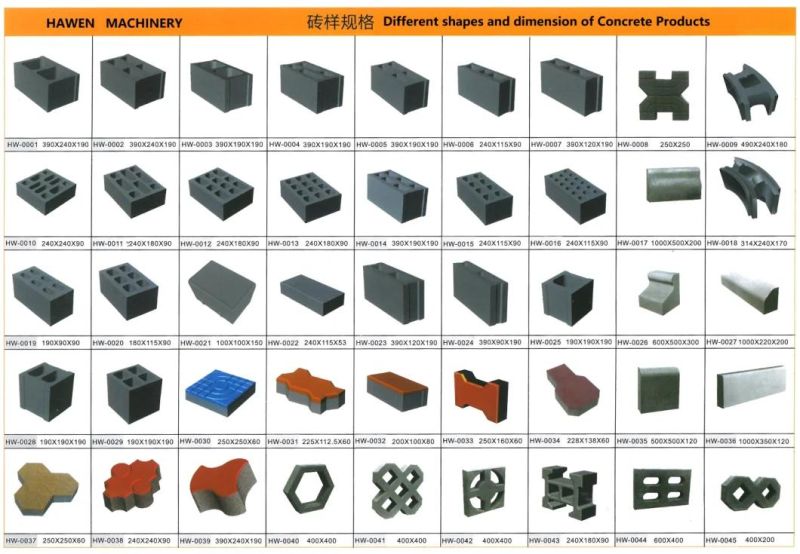

Hollow blocks, solid block,soild brick, paving stones

with or without face mix, garden and landscaping products, slabs,

curbstones, grass paver, slope blocks, interlocking paver, etc.

Capacity of QT6-15 Automatic block making machine

Processing equipment in the workshop

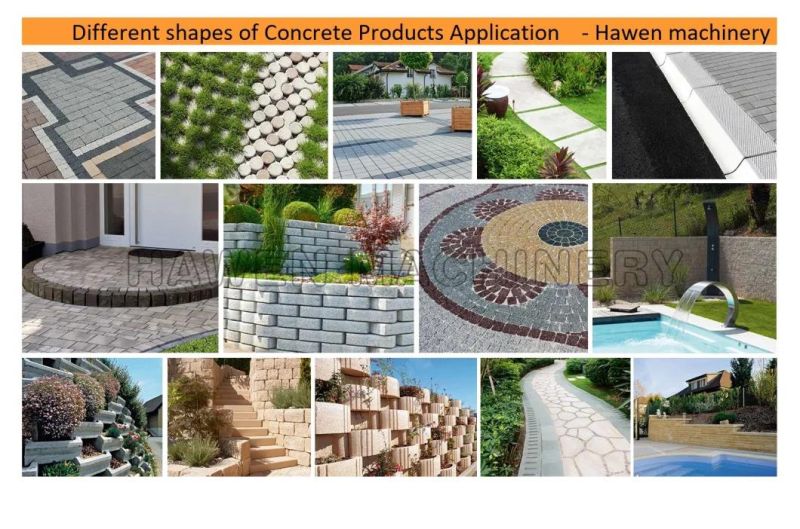

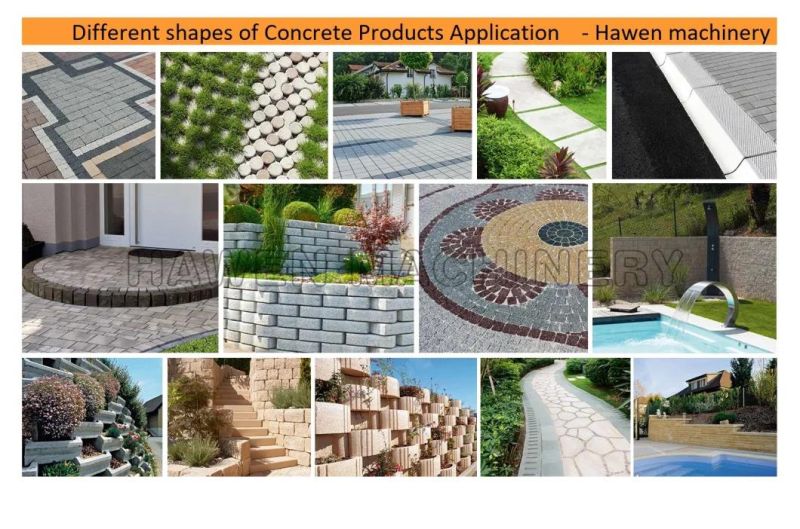

Application of QT6-15 Block Making Machine at site

Container loading in workshp for customers overseas

Block and Brick Sample

Application:

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.

with or without face mix, garden and landscaping products, slabs,

curbstones, grass paver, slope blocks, interlocking paver, etc.

Capacity of QT6-15 Automatic block making machine

Processing equipment in the workshop

Application of QT6-15 Block Making Machine at site

Container loading in workshp for customers overseas

Block and Brick Sample

Application:

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order