Cement Concrete Block Machine Qt10-15 Block Mold Machine

Dongyue Machinery Group Co., Ltd.- Certification:CE, ISO9001: 2000

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

- Experience:Nearly 20 Years

- Block Machine Method:Hydraulic Pressure and Vibrate

Base Info

- Model NO.:QT10-15

- Hydraulic Station:Taiwan Jiugang

- Welding:Carbon Dioxide Welding

- PLC:Mitsubishi &Siemens

- Motor:Siemens &ABB

- AC Contactor:Schneider& Omron

- Mold:Heat Treated

- Main Material:Sand, Flyash, Cement, Crushed Stone

- Oversea Ofice:India, Indonesia, Vietnam, Russia

- Transport Package:according client requirement

- Specification:ISO9001

- Trademark:dongyue

- Origin:shandong china

- HS Code:84748090

- Production Capacity:100 set per month

Description

Basic Info.

Model NO. QT10-15 Hydraulic Station Taiwan Jiugang Welding Carbon Dioxide Welding PLC Mitsubishi &Siemens Motor Siemens &ABB AC Contactor Schneider& Omron Mold Heat Treated Main Material Sand, Flyash, Cement, Crushed Stone Oversea Ofice India, Indonesia, Vietnam, Russia Transport Package according client requirement Specification ISO9001 Trademark dongyue Origin shandong china HS Code 84748090 Production Capacity 100 set per monthProduct Description

Company introduction

Dongyue Machinery Group are leading cement brick making machine in

China.Our brick machine has been exported to more thn 60 countries.

Oversea offices are built in India.Indoneisa.Vietam etc.We have 32 fly

ash brick making machine plant in India.They spread in Bhubaneshwar ,

Coimbatore,Rajkot,Koltata,bangalore,Indore etc.Two after sale service

centers and spare stock center are available in Ahmedabad and Bhubaneshwar .India engineers are well trainned in China and can install the

machine in India directly.

2. Cement Concrete Block Machine Qt10-15 Block Mold Machine main advantages

(1) Full automatic and hydraulic automatic block making machine , can produce all kinds of bricks,

and just change the moulds, such as the solid bricks, hollow blocks, paver blocks and so on.

(2) German Siemens motors

(3) Japan Mitsubishi PLC

(4) Omron travel switch

(5) The moulds: We adopt the heat treatment technique to increase the lifespan of the moulds

(6) Certificates: SGS/CE/ISO9001 2008

(7) Mould heat treatment & carburization technology

(8) Strong High-Strength Steel Structure

3. Cement Concrete Block Machine Qt10-15 Block Mold Machine each part detals

1) Three bin batching plant

function: This is the starting point of the Production process. It consists of three loading bins and

one weighing bin. It also contains belt conveyers to convey materials from loading bins to weighing

bin. Batching and weighing is done by PLC control. We can load three different types of material into

the loading bin.

2) JS750 MIXER

Function:All the ingredients are mixed in this mixture machine. The mixing time and speed is controlled

by PLC. The inbuilt water pump adds water to the mix automatically, as per requirement.

3) Germen Siemens motor and Janpnese Mitsubish PLC

4) Stacker

4 .Technical characteristics of Cement Concrete Block Machine Qt10-15 Block Mold Machine :

1). Automatic block production lines, includees a cluster cars, steam curing cellar of block production

line , are of high degree of automation .It can bring the fully-automated production process of batch charging, stir forming , transmission and curing, palletizing and packing into practice.

2). our machine have passed Europe CE and ISO9001 standard.we use Germany SIEMENS motors,Japanese MITSUBISHI PLC control system

3).Use three same size oil cylinder,will work at the same time,to insure the same density and high

quality of the blocks.

4).Use 360°revoling method to make the material more uniform.

5).Use the heat treatment technial to deal with the mould,so the useful life of the mould is more

longer.

6).Install the cooling pump to cool down the oil ,so to insure the normal work of the Hydraulic

System.

7).Install the waste recycling tank,could reduce the waste of materials

5.General notice

1). Customized color is available based on previous notice.

2). The third party inspection is available.

3). If needed, the seller can help the buyer to handle shipping and insurance.

4). Marking and package shall be arranged according to applicable international

requirements.

5). Guarantee: Our block machine has been taken under guarantee by the seller from

the date of commissioning within 12 months on the premise of regular use of the buyer.

An Acceptance Act will follow to inspect the application of the equipment.

6). Installation & commissioning is available based on the clients' requirement.

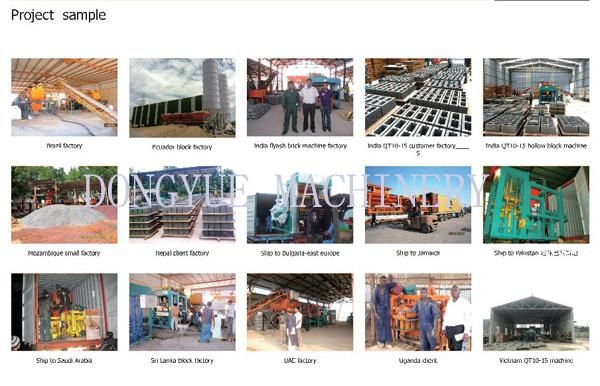

6.project sample

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr |

| 4 00X200X200 | 10 | 1500-1800 |

| 400X100X200 | 20 | 3000-3600 |

| 2 25 X1 12.5 X60 | 27 | 4050-4500 |

250 X 60 | 14 | 2100-2400 |

200X100X60 | 35 | 5250 |

| 200X165X60 | 20 | 3000 |

250x250x60 | 8 | 1200-1650 |

| Dimension of host machine | 3800×2300×3550mm | Host machine power | 51.2KW |

| Moulding area | 1025×810mm | Vibration force | 90-110KN |

| Moulding period | 15-20S | Mixer model | JS750 |

| The size of the pallet | 1300×900×30mm | General water Consumption | 12T/every day |

| Weight of the host machine | 11.5T | Voltage | 380V |