Double Layer Galvanized Sheet Metal Roof Tile Rolling Machine

Tianjin Haixing Imp. & Exp. Co., Ltd.- Tile Type:Glazed, Trapezoidal Roof

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Usage:Roof, Wall, Floor

- Transmission Method:Chain Drive

Base Info

- Model NO.:HX-760+780

- Main Motor Power:5.5kw, 7.5kw, 10.5kw or as Actual Demands

- Voltage:380V,50Hz,3 Phase

- Productivity:1.5-3m,Min, 8-12m,Min

- Mainframe:350mm, 400mm, 450mm H Beams, 45# Steel

- Chain:1 Inch - 2inch According to Machine Demands

- Wheel:45# Steel

- Shaft Diameter:70mm - 90mm (Depends on Different Design)

- Shearing Knife:Cr12 , Cr12MOV, Heat Treatment, HRC 58-60ºC

- Cutting Method:Hydraulic Guide Column Cutting

- Control System:PLC Control System, 360 Degree Rotation

- PLC Display Languages:Chinese, English, (Spanish or Russian)

- Number of Rolls:Common 9 Rolls - 25rolls

- Feeding Thickness:0.3-1.0mm

- Length Tolerance:2mm

- Cutting Tolerance:1mm

- Transport Package:Standard Export Packing: 1 X 40gp Container

- Specification:6500*14000*1300mm

- Trademark:HX

- Origin:Hebei, China

- HS Code:84552210

- Production Capacity:200 Sets Per Month

Description

3

input length of the sheets and numbers of the piece you need,

then the machine

Company profile

Tianjin Haixing Imp & Exp Co., Ltd. is a manufacturer and exporter specializing in the design, development and production of cold roll forming machines. The company is located in the northwest of Tianjin, China, and cooperates with a number of production plants and related companies.

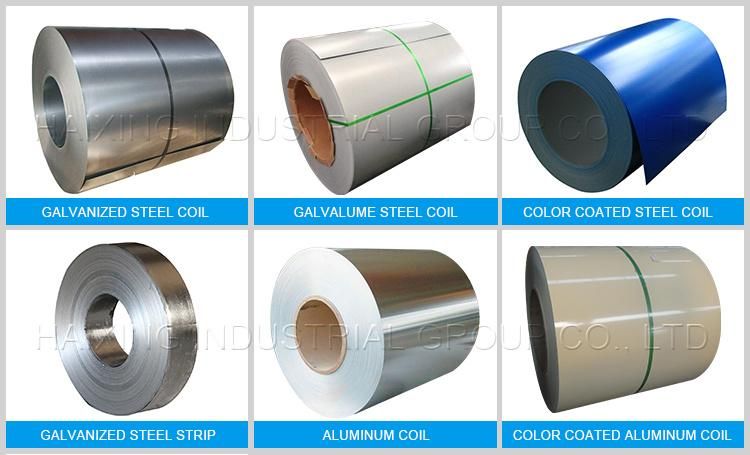

The company is specialized in manufacturing roof roll forming machines, floor deck roll forming machines, leveling and shearing machines, decoilers, C and Z purlin roll forming machines, slitting production lines, light steel keel roll forming machines, sandwich panel roll forming machine, highway guardrail roll forming machine, downspout & rain gutter roll forming machine, shutter door & door frame roll forming machine, and other associated equipment. We also provide products such as galvanized steel coils, galvalume steel coils aluminum coils, color steel coils.

As a production base of cold roll forming machines with a long history, we have cooperated with a number of production plants and related enterprises to focus on the design, development, and production of cold-formed machines. All products meet international quality standards and are highly evaluated in different markets around the world, including Asia, Africa, Europe, South America, Oceania and more.

FAQ1. Q: Are you a manufacturer? A: Yes,we are a manufacturer for cold roll forming machine over 12 years.

2. Q: if you can accept OEM? Design and manufacture according to our photo.

A: Yes, we can accept OEM, we owned an expert engineer team, professional design CAD drawings and use famous brand components according to your demands.3. Q: What's the warranty for your machine? A: We provide 2years guarantee and provide lifetime technical support. 4. Q: How many workers are needed for the machine operation A: One worker is enough, the machine uses an automatic PLC control system.5. Q. Do you have after-sales support? A: Yes, Our engineer can supply remote-video technical support and online support to teach your worker.

6. Q. Can you be responsible for transport?

A. Yes, we owned an expert export team, we can arrange for you to your destination port or address.

7. Q: What service can you provide before order?

A: About the pre-sale service, We provide professional solutions according to your demands, such as design, technical parameter, delivery flow, etc. At the same time, we can supply an invitation letter for your visit to our factory and showing the machine operation for you.8. Q: What is the after-sale service? A: We will supply lifetime technical support,quick-wear parts within 2 years, we also can provide field maintenance and repair service.9. Q: Any other service?A: We can help you purchase raw material for machine, help you check ship date, update for your ship date, etc.10. Q: Any certificationA: Yes, we have CE SGS ISO certification.