Hr1-10 Automatic Soil Interlocking Brick Machine Soil Lego Interlocking Brick Machine in Africa

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Warranty:3 Years

- Certification:CE, ISO

Base Info

- Model NO.:HR1-10

- Customized:Customized

- Automatic Grade:Automatic

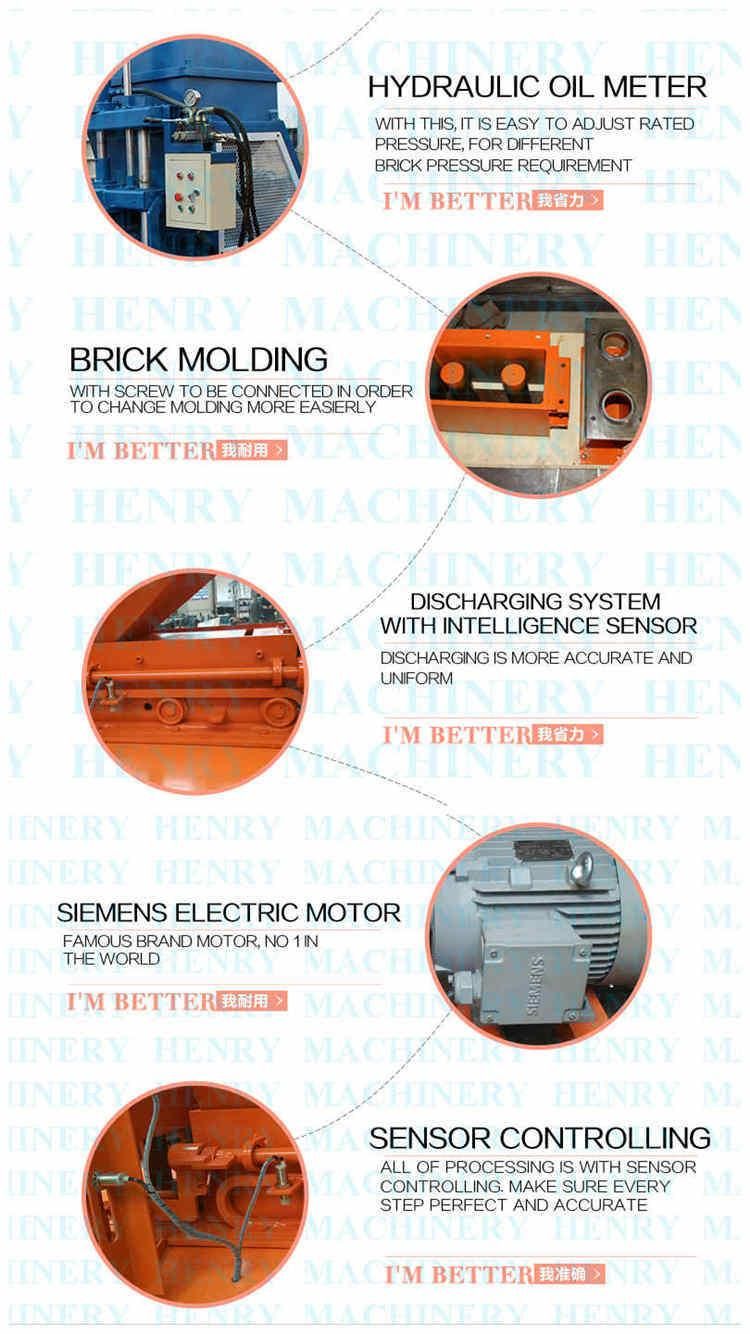

- Type:Hydraulic Shock

- Colour:According to Your Demand

- Motors:Siemens

- Voltage:380V,50Hz(Adjustable)

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Molding Cycle:6-10s

- Weight:1000kg

- Cooling Way:Water Cooling

- Rated Pressure:16-25MPa

- Overall Size:1000X1000X1800mm

- Model:Hr1-10

- Rated Power:5.5kw or 15HP Diesel Engine

- Transport Package:Iron Box or Wood Box with Angle Rion Frame

- Specification:CE SGS ISO

- Trademark:HENRY

- Origin:China(Mainland) Shandong Linyi

- HS Code:8474802000

- Production Capacity:4800PCS,Day

- Package size per unit product:250.00cm * 150.00cm * 210.00cm

- Gross weight per unit product:2200.000kg

Description

Basic Info.

Model NO. HR1-10 Customized Customized Automatic Grade Automatic Type Hydraulic Shock Colour According to Your Demand Motors Siemens Voltage 380V/50Hz(Adjustable) After-Sales Service Provided Engineers Available to Service Machinery Overseas Molding Cycle 6-10s Weight 1000kg Cooling Way Water Cooling Rated Pressure 16-25MPa Overall Size 1000X1000X1800mm Model Hr1-10 Rated Power 5.5kw or 15HP Diesel Engine Transport Package Iron Box or Wood Box with Angle Rion Frame Specification CE SGS ISO Trademark HENRY Origin China(Mainland) Shandong Linyi HS Code 8474802000 Production Capacity 4800PCS/DayPackaging & Delivery

Package size per unit product 250.00cm * 150.00cm * 210.00cm Gross weight per unit product 2200.000kgProduct Description

HR1-10 Wholesale Price Automatic Soil Interlocking Brick Machine soil lego interlocking block machine In Africa

Advantages of HR1-10 Wholesale Price Automatic Soil Interlocking Brick Machine soil lego interlocking block machine In Africa

1. fully automatic production line ,soil interlocking brick machine

2. fastest shaping shift, 6 second

3. self-picking system, saving labor

4. 15 Mpa pressure

HR1-10 block machine specification

| rated power | 3 kw or 15 HP diesel engine |

| overall size | 1000x1000x1800mm |

| weight | 1000kg |

| cycle | 10 seconds |

| electricity source | 380v/50HZ (adjustable) |

| Cooling way | Water cooling |

| Switch | Automatic |

| rated pressure | 16mpa |

HR1-10 Wholesale Price Automatic Soil Interlocking Brick Machine soil lego interlocking block machine In Africa production

Company profile

Our sevice

we have go big after sale service team , they are all the experience

technician , over 20 workers have the passport ,they all have the oversea

experience.

So we not only have good service in the pre service , we also think highly

of the after sale service.