120mm Wall Panel Mould for Lightweight Wall Panel Production

OYADE (Shandong) Machinery Equipment Co., Ltd.- Product Type:Build Material

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:CE, ISO

- Condition:New

Base Info

- Model NO.:YR-V-20181005D

- Customized:Customized

- Item:Lightweight Wall Panel Machine

- Panel Length:2440mm-3300mm

- Product Width:610mm

- Equipment Capacity:30,000sqm~500,000sqm Per Year

- Machine Features:High Equipment ,Low Failure Rate ,Muli-Function,Lo

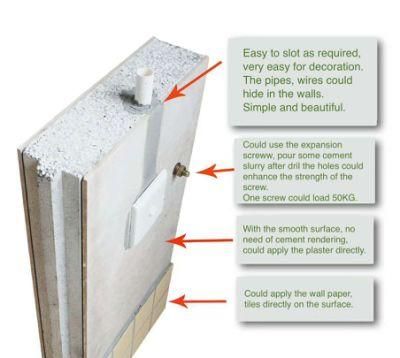

- Panel Usage:Interior Wall ,Floor ,Exterior,Roof,Ceiling

- Steel Plate:Cold-Roll Steel Sheets

- Mixer Capacity:1.5,2.0,2.5,3

- Injection Way:by Pump

- Transport Package:Bulk Packing

- Specification:5containers

- Trademark:OYADE

- Origin:China

- HS Code:8474802000

- Production Capacity:300sets,Year

Description

Basic Info.

Model NO. YR-V-20181005D Customized Customized Item Lightweight Wall Panel Machine Panel Length 2440mm-3300mm Product Width 610mm Equipment Capacity 30,000sqm~500,000sqm Per Year Machine Features High Equipment ,Low Failure Rate ,Muli-Function,Lo Panel Usage Interior Wall /Floor /Exterior/Roof/Ceiling Steel Plate Cold-Roll Steel Sheets Mixer Capacity 1.5/2.0/2.5/3 Injection Way by Pump Transport Package Bulk Packing Specification 5containers Trademark OYADE Origin China HS Code 8474802000 Production Capacity 300sets/YearProduct Description

Feature of this type vertical forming machine

1.Double function

We have double function mould car , it not only can produce composited and solid panel to suit market demand .

2.High Quality Surface plate

Our mould car surface plate used cold roll steel plate ,which thickness can be 3mm to 5mm , so that can guarantee the wall panel are straight ,besides the plate is durable

3.steel rail of the forming machine

The raw material for steel rail is wear-resistant casting steel , which is same to the high speed train.

4.large capacity

vertical mould car has a large cpacity than horizontal type such as for 90mm panel , vertical mould car can produce 42pcs /car , for horizontal type only 10pcs /car .

5.Automatic demoulding system

Semi-automatic mould car demould 1 pcs per time . Full automatic forming machine demould 20pcs per time .

How does it work

For full automatic demoulding system ,it can save labors and improve working efficience

Firstly , need use opening and closing machine to open the mould car automatically.

Then ,use the full automatic demoulding machine to pull out the panel, 20pieces one time ,then put them together and then lay down the panel ,

After then , the forklist will move the panel outside for natural curing .

Welcome you contact with us for more details .