Germany Original Fully Automatic Zenith 940 Cement Concrete Brick Block Machine

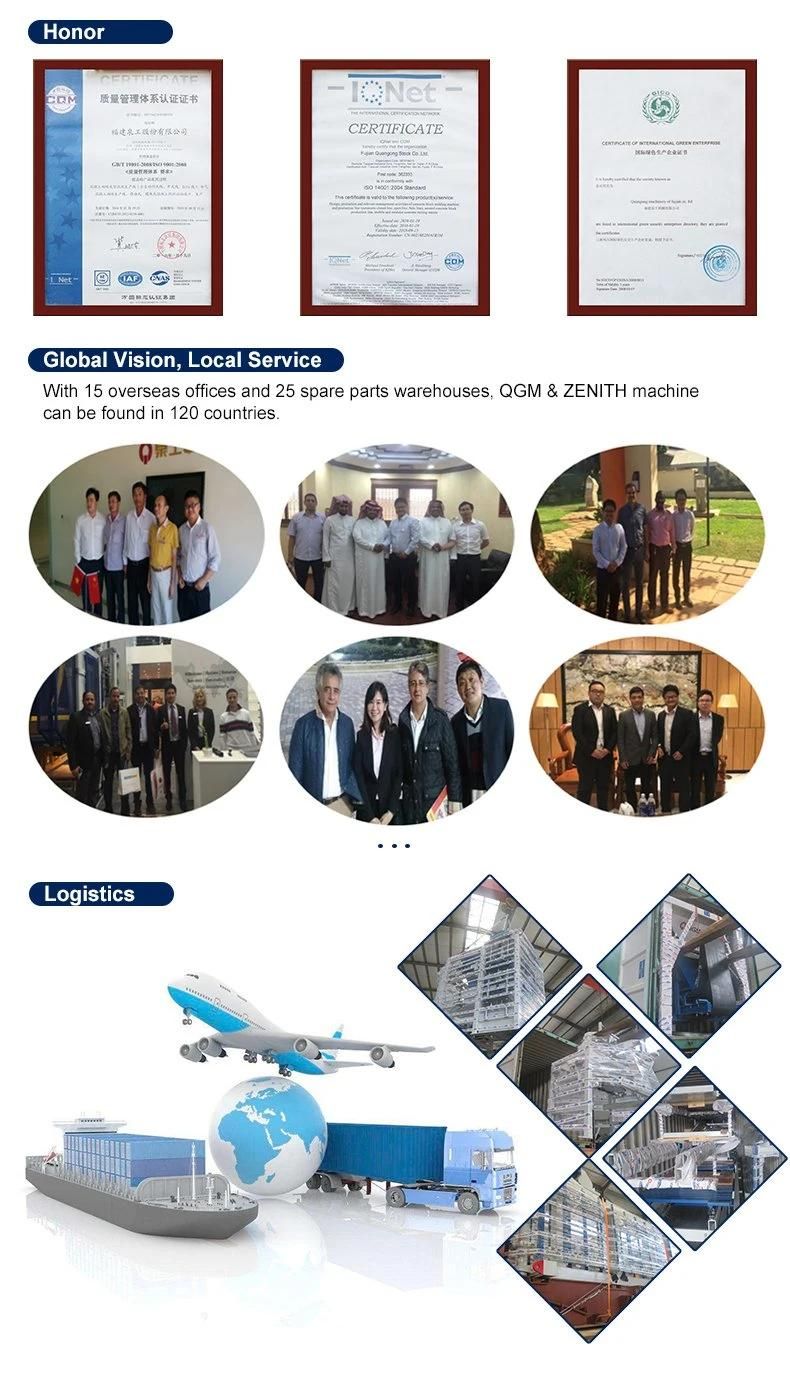

Quangong Machinery Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

- Condition:New

- Product:Hollow,Solid,Paver Blocks

Base Info

- Model NO.:ZENITH 940

- Brick Raw Material:Concrete

- Back Concrete Hopper Volume Loader:1200L

- Back Concrete Hopper Volume Conveyor:2000L

- Face Concrete Hopper Volume Loader:800L

- Face Concrete Hopper Volume Conveyor:2000L

- Loader Feeding Height Max:2800mm

- Max.Production Width:1240mm

- Max.Production Depth:1000mm

- Transport Package:Standard Seaworthy Packing

- Specification:Weight (with face unit and mould): 15, 500kg

- Trademark:ZENITH

- Origin:Germany

- HS Code:8474802000

- Production Capacity:Paver 200*100*60mm: 817 Sqm

Description

Control system:Siemens S7-1500,position detection of main movements by limit switchesControl system:Siemens S7-1500,digital path measuring system for all main movement axes

Technical details are subject to changes without prior notice.Pictures of equipment shown are examples only.Photos may include optionals as per customer's demand.

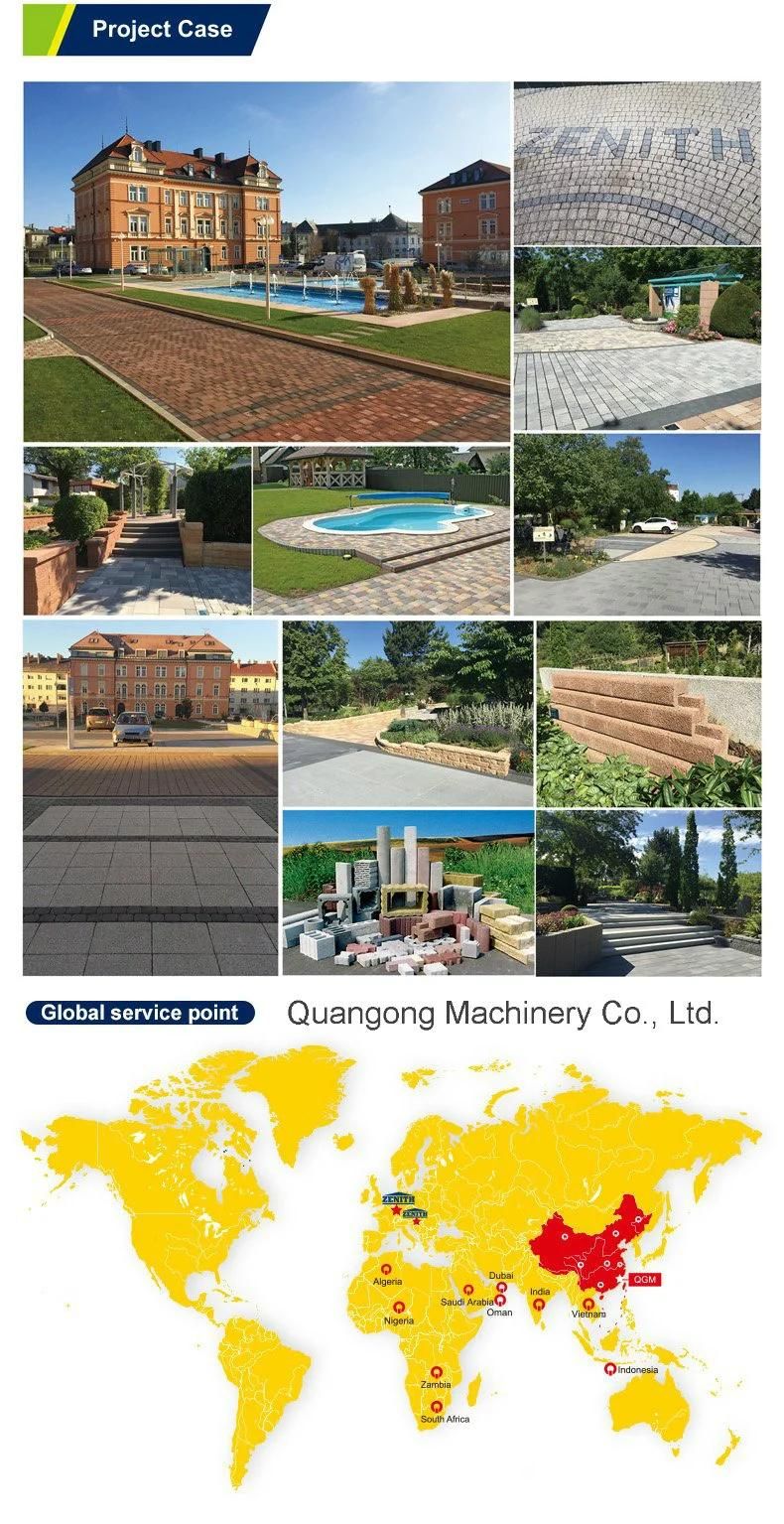

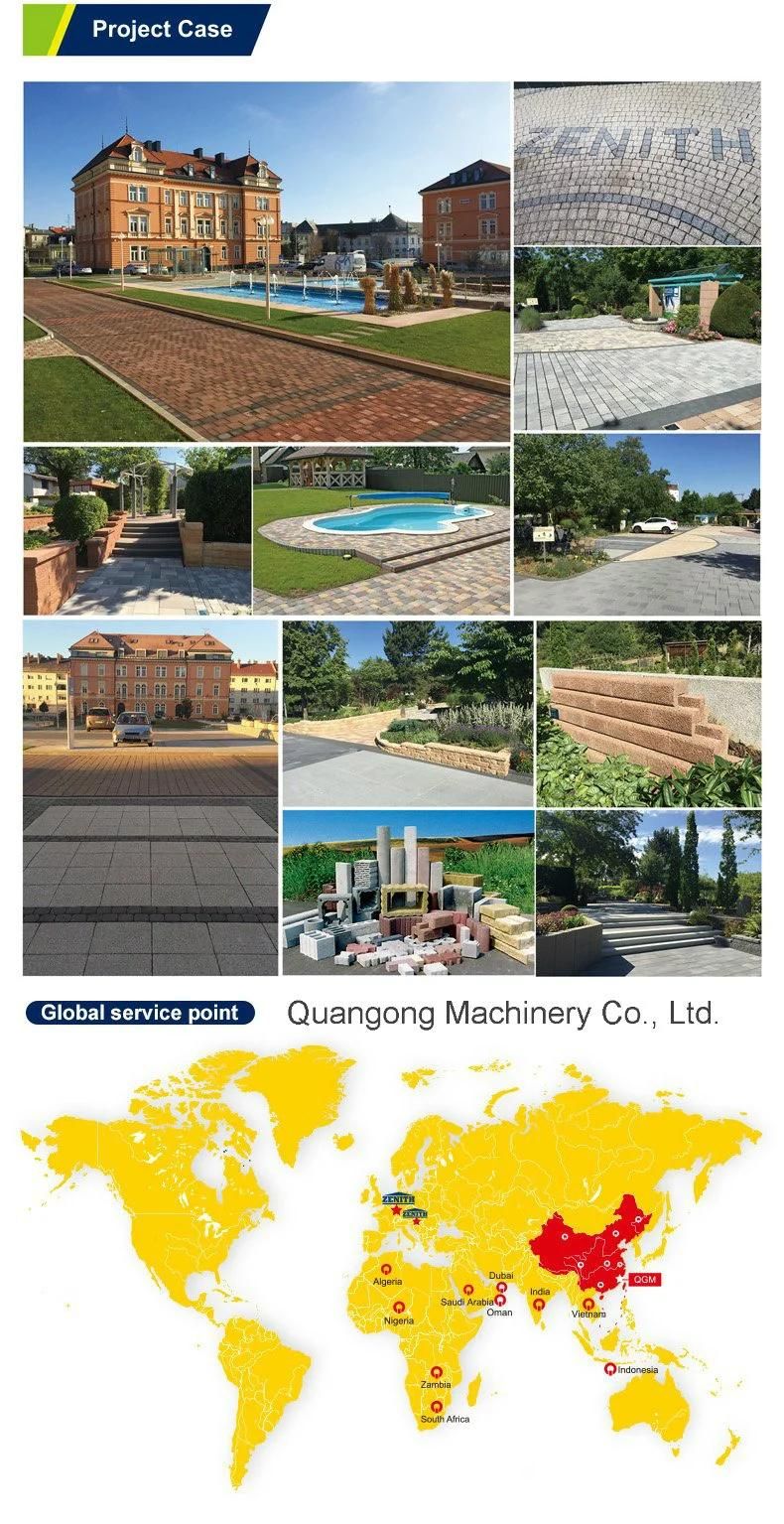

QGM ZENITH has set up overseas concrete block machine after-sales offices all over the world to guarantee the fast and high quality after sales service for global customers. There are 10 overseas offices for the after-market service of concrete brick machine, including Saudi Arabia, India, Dubai, Oman, Algeria, Nigeria, Zambia, South Africa, Vietnam, Indonesia etc.

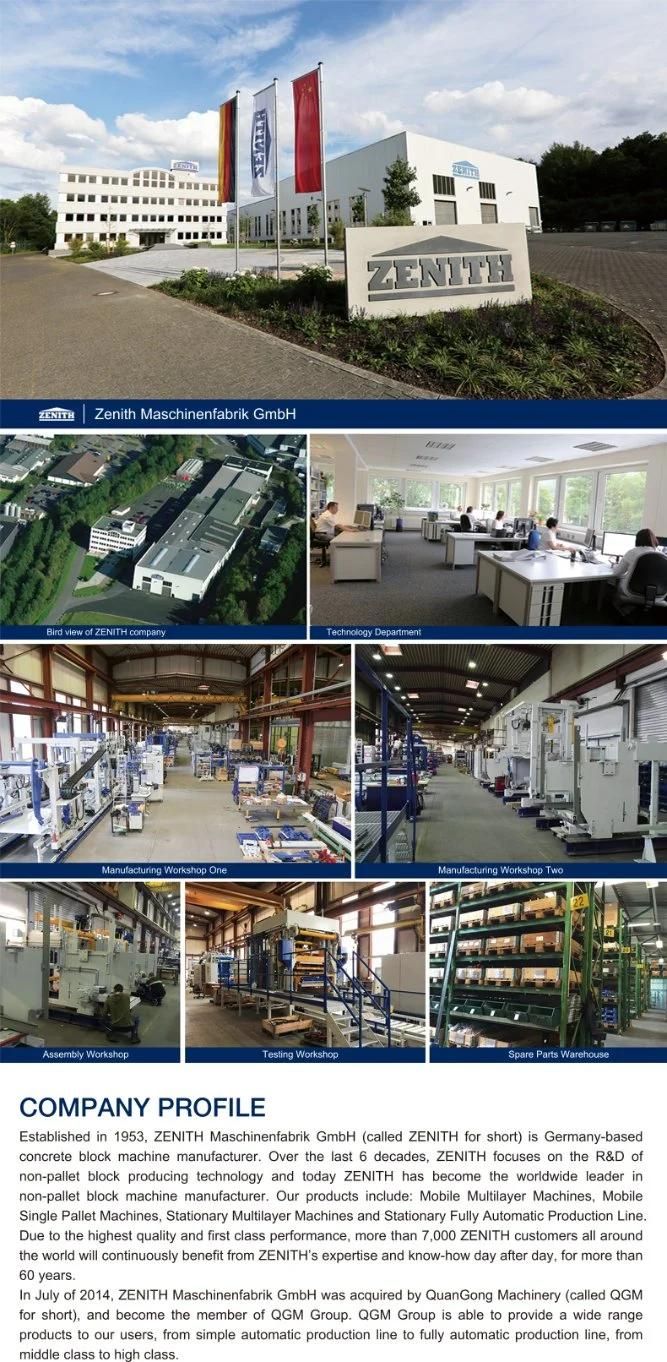

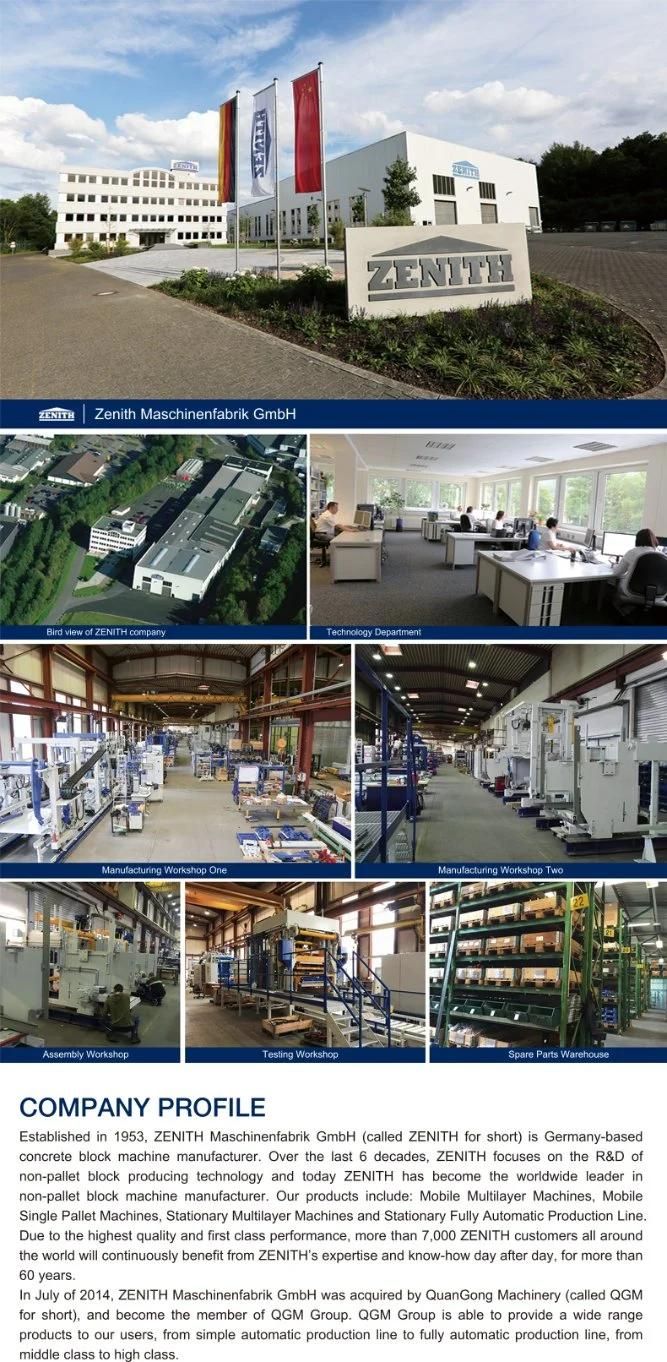

FAQ:1.Q: For ZENITH940 concrete brick machine, What is the best price you could offer?A: The price of a concrete block production line includes batcher, mixer, brick machine, stacker etc, so the price varies a lot based on the client's selection of the auxiliary equipment and configuration. QGM ZENITH is glad to provide quotation for customers who could kindly provide detailed technical requirements such as block type, block size, capacity requirement, budget range etc. Please kindly contact us for further discussion.2.Q: What does the number 6, 10, 900, 1000 mean in the QGM block machine?A: Take block machine QT6 as an example, 6 means the brick machine could make 6 pieces of hollow blocks at the size of 390*190*190mm. The same goes with QT10. For the ZN900C, ZN1000C, these two concrete block machines are updated with Germany Zenith design after 2014. ZN900C and ZN1000C respectively makes 9 and 10 pieces of the same cement blocks mentioned above.3.Q: For the concrete block machines from QGM ZENITH, how do you do the installation, commission and after sales service?A: After the arrival of the block machine on site, QGM will appoint technical engineers to support with the installation, commissioning of cement block production as well as the operator training and test. For after-sales service, QGM has set up overseas offices in different areas for future support, including Algeria, Dubai, India, Indonesia, Nigeria, Oman, Saudi Arabia, South Africa, Vietnam etc.4.Q: What is the relationship between Quangong Machinery Co., Ltd and Germany Zenith?A: In 2014, QGM fully acquired Zenith Maschinenfabrik GmbH. Benefiting from the close collaboration between Germany Zenith technology and QGM China Manufacturing center, QGM Group is able to provide a wide range of concrete block machines to global users, from simple automatic production line to fully automatic production line, from stationary automatic block making machine to mobile automatic block machine.5.Q:What is the strength of the cement bricks that QGM machines could make?A: The strength of concrete blocks is related to the properties and ratio of the raw material, the strength of cement, the vibration force, the operation of the concrete block making machine, the regular maintenance of the complete production line etc. The QGM technical engineer would test the machine with the raw materials customer provides on site to make the premium concrete blocks then train the customer's operator. With the proper raw materials and recipe, accurate operation, stored formula in Siemens control system, regular maintenance of the block machine, the QGM block machine should be able to make satisfactory concrete blocks.6.Q:What payment is acceptable?A:30% of contract value by T/T as advance payment; 70% of contract value by T/T or L/C before delivery.

Technical details are subject to changes without prior notice.Pictures of equipment shown are examples only.Photos may include optionals as per customer's demand.

QGM ZENITH has set up overseas concrete block machine after-sales offices all over the world to guarantee the fast and high quality after sales service for global customers. There are 10 overseas offices for the after-market service of concrete brick machine, including Saudi Arabia, India, Dubai, Oman, Algeria, Nigeria, Zambia, South Africa, Vietnam, Indonesia etc.

FAQ:1.Q: For ZENITH940 concrete brick machine, What is the best price you could offer?A: The price of a concrete block production line includes batcher, mixer, brick machine, stacker etc, so the price varies a lot based on the client's selection of the auxiliary equipment and configuration. QGM ZENITH is glad to provide quotation for customers who could kindly provide detailed technical requirements such as block type, block size, capacity requirement, budget range etc. Please kindly contact us for further discussion.2.Q: What does the number 6, 10, 900, 1000 mean in the QGM block machine?A: Take block machine QT6 as an example, 6 means the brick machine could make 6 pieces of hollow blocks at the size of 390*190*190mm. The same goes with QT10. For the ZN900C, ZN1000C, these two concrete block machines are updated with Germany Zenith design after 2014. ZN900C and ZN1000C respectively makes 9 and 10 pieces of the same cement blocks mentioned above.3.Q: For the concrete block machines from QGM ZENITH, how do you do the installation, commission and after sales service?A: After the arrival of the block machine on site, QGM will appoint technical engineers to support with the installation, commissioning of cement block production as well as the operator training and test. For after-sales service, QGM has set up overseas offices in different areas for future support, including Algeria, Dubai, India, Indonesia, Nigeria, Oman, Saudi Arabia, South Africa, Vietnam etc.4.Q: What is the relationship between Quangong Machinery Co., Ltd and Germany Zenith?A: In 2014, QGM fully acquired Zenith Maschinenfabrik GmbH. Benefiting from the close collaboration between Germany Zenith technology and QGM China Manufacturing center, QGM Group is able to provide a wide range of concrete block machines to global users, from simple automatic production line to fully automatic production line, from stationary automatic block making machine to mobile automatic block machine.5.Q:What is the strength of the cement bricks that QGM machines could make?A: The strength of concrete blocks is related to the properties and ratio of the raw material, the strength of cement, the vibration force, the operation of the concrete block making machine, the regular maintenance of the complete production line etc. The QGM technical engineer would test the machine with the raw materials customer provides on site to make the premium concrete blocks then train the customer's operator. With the proper raw materials and recipe, accurate operation, stored formula in Siemens control system, regular maintenance of the block machine, the QGM block machine should be able to make satisfactory concrete blocks.6.Q:What payment is acceptable?A:30% of contract value by T/T as advance payment; 70% of contract value by T/T or L/C before delivery.