Aluminium Window Door Making End Surface CNC Milling Machine

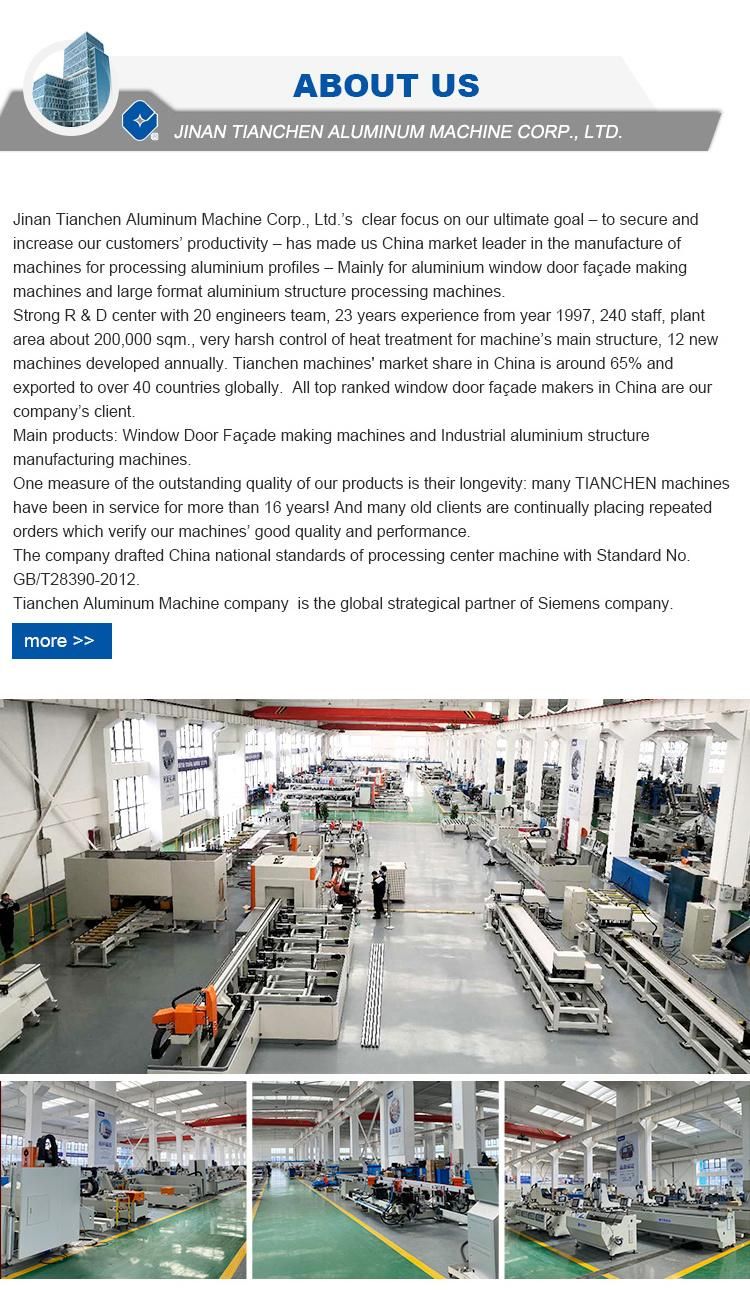

Jinan Tianchen Smart Machine Co., Ltd.- Condition:New

- Certification:ISO, CE

- Automatic Grade:Automatic

- CNC or Not:CNC

- Voltage:380V

- Product Name:Aluminium CNC End Milling Machine

Base Info

- Model NO.:LXD2S-CNC-300

- Application:Window Door Fabrication Industry

- Working Material:Aluminum Profiles

- Worktable Numbers:2

- Main Feature:Fully Automatic and High Efficiency

- CNC System:Schneider

- Usage:Window Customized Production

- Function:Milling Mullion End Surface

- Milling Tools Number:3

- Tool Movement Type:Automatic

- Transport Package:by Container 20gp

- Specification:5000x2100x2300mm (LxWxH)

- Trademark:Tianchen

- Origin:Jinan, China

- HS Code:84614090

Description

Basic Info.

Model NO. LXD2S-CNC-300 Application Window Door Fabrication Industry Working Material Aluminum Profiles Worktable Numbers 2 Main Feature Fully Automatic and High Efficiency CNC System Schneider Usage Window Customized Production Function Milling Mullion End Surface Milling Tools Number 3 Tool Movement Type Automatic Transport Package by Container 20gp Specification 5000x2100x2300mm (LxWxH) Trademark Tianchen Origin Jinan, China HS Code 84614090Product Description

CNC End Milling Machine for Making Aluminium Window DoorModel LXD2S-CNC-300

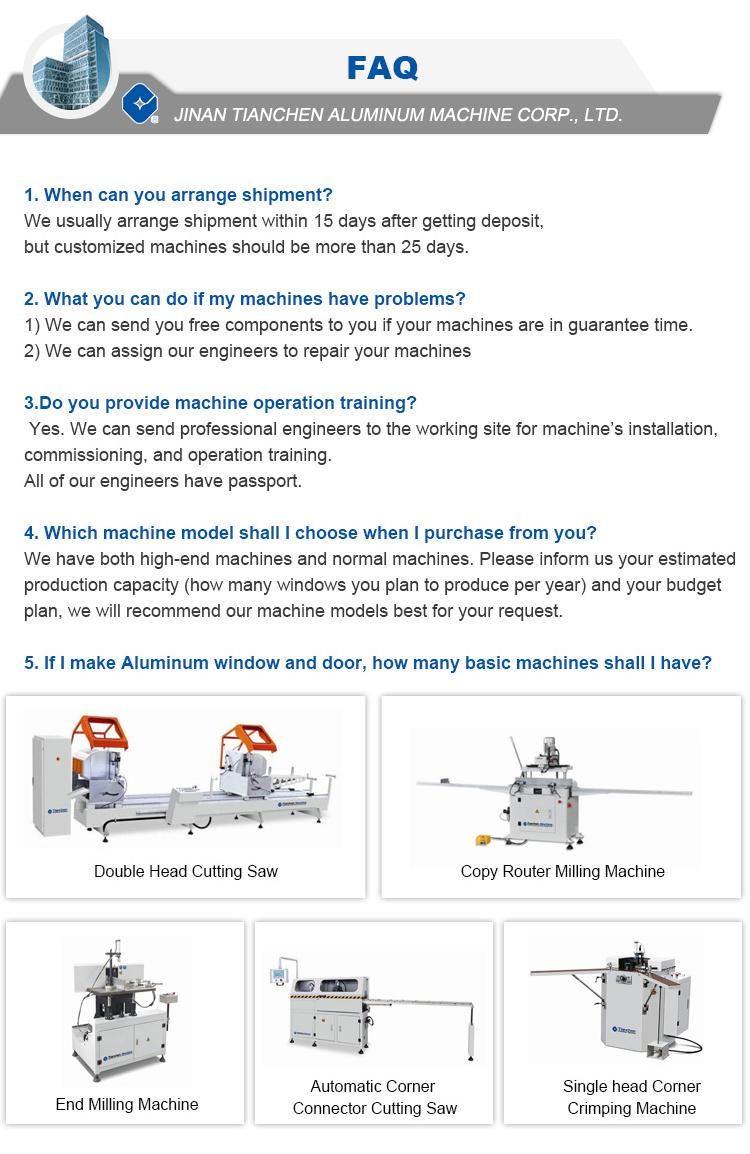

1. Machine Features:☆Suitable for sawing and milling of end surface tenon and step surface of stile profile in aluminum doors and windows;

1. Machine Features:☆Suitable for sawing and milling of end surface tenon and step surface of stile profile in aluminum doors and windows;☆ Install two sawing and milling motors, one for horizontal milling and the other for vertical slitting (and can be automatically turned into horizontal milling), taking into account the end milling operations of various sections of mid-straight profiles and strengthened stiles, with very good versatility

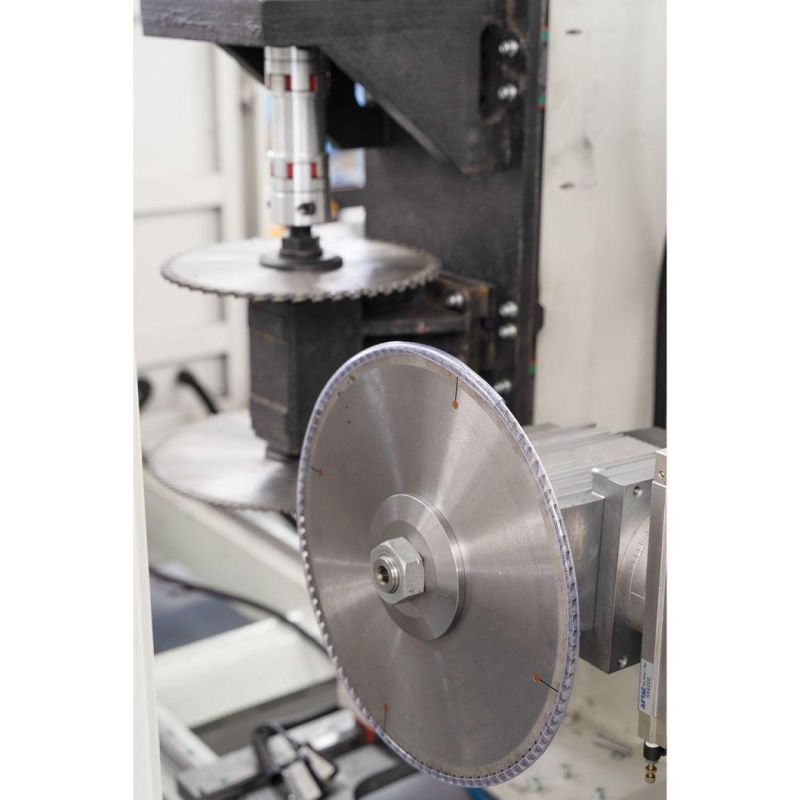

☆ Horizontal milling adopts high-power motor, double saw blade or combined milling cutter design to improve processing efficiency. Advanced connection structure, convenient tool replacement;

☆ The horizontal/vertical vertical slitting saw blade can be adjusted automatically, and the application range is wider;

☆ The left and right double work table design, interactive feeding mode, higher efficiency, and can process two different sections of profiles at the same time, more flexible and convenient to use;

☆ The two milling motors are controlled by a five-axis CNC servo system, without manual adjustment, and can be processed quickly and conveniently by selecting a preset program; it can continuously process profiles of different sections.

☆ The feed direction adopts a large-lead ball screw, which runs faster and more stable.

☆ The feed system adopts the structure of a servo motor screw linear guide rail pair, which can preset the speed for different thickness profiles, with low vibration and high processing accuracy.

☆ Controlled by Schneider CNC system, five sets of servo axis, stable and reliable, and can be connected to the MES server computer to realize network processing, and automatically convert the stile section into a processing program.

☆ Program processing can be automatically called by scanning code, easy to operate.

2. Main Parameters:

- Power:380V 50Hz

- Air Source Pressure: 0.5~0.8Mpa

- Milling Motor Power:4.0 KW + 2.2 KW

- Motor Rotating Speed:2800rpm

- Spindle Diameter:30mm

- Horizontal Infeeding Travel:0~1500mm

- Max. Tool Diameter:Sawing Bladeφ350,Milling Tool φ300

- Work Table Size:510×340mm

- Milling Slot's Max. Size (Horizontal):200 Height ×100 Depth ×500mm Width(φ300 Sawing Blade or Milling Tool)

- Milling Slot's Max. Size(Vertical):80 Height×50 Depth×500mm Width(φ300 Sawing Blade or Milling Tool)

- Overall Dimension:5000×2100×2300

- Servo System:Schneider

- Slitting Motor:Italy SEIMEC

- Low Voltage Electric Components:Siemens

- Ball Screw:Taiwan HIWIN/PMI/ABBA