High Speed Servo Concrete Automatic Block Making Machine

Quanzhou Hawen Machinery Co., Ltd.- After-sales Service:Engineer Available to Abroad

- Warranty:One Year After Installation

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

Base Info

- Model NO.:QT10

- Require Factory Area:4000-5000sqm

- Shed Required:25X20X6-8m

- Pallet Size:1100-1150 X 950mm

- Weight of Main Machine:12 Ton

- Plant Power:100kw Including Batching Machine and Mixer

- 8" Hollow Block:10PCS,Drop

- 6" Hollow Block:12PCS,Drop

- Rectangle Paver:36PCS,Drop

- Moulds:Can Be Customized

- Transport Package:Standard Ocean Packing

- Specification:9800x2300x2800mm

- Trademark:HAWEN

- Origin:Quanzhou City, Fujian, China

- HS Code:84748090

- Production Capacity:500sets,Year

Description

Production per Shift (8 Working Hours):Hollow Block (400x200x200mm): 15,000~16,000 pcs Hollow Block (400x150x200mm): 17,000~19,000 pcs Indian Fly Ash brick (230x75x110mm): 76,000~77,000pcs Zigzag shape Paver(225*112.5*60/80mm): 40,000~50,000pcs Rectangle Paver (200x100x60-80mm): 52,000~69,000pcs Vibrating Frequency: 50 HZ Motors Power: 51KW For Main forming machine parts only Machine Dimensions: 9800x2300x2800mm Pallet Size: 1100x950mm or 1200x900mm Gross Weight: About 12T Raw Materials: crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes Applied Products: concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. Applied Fields: widely used in buildings, road pavings, squares, gardens, landscaping, city constructions

Brief Introduction

HWG-1000 block making machine,using servo motor vibration, it is more energy saving and the response speed is faster. With imported vane pump and hydraulic valve make the equipment run stably and the forming speed faster, which can greatly reduce the cost of brick making.The special vibration and feeding system of this machine can meet the demand of different blocks production for customers,like Hollow block, Solid block,grass-planting paver, curb stones, slope-protect bricks, inter-lock blocks and so on.

Advantage of HAWEN Block Making Machine

Servo motor vibration technology

Through the use of Servo motors, smooth out the machine cycle resulting in the production of higher quality concrete products. Equally important, it extends the life of machine and mold parts.

It precisely control the acceleration and deceleration of the bull gear maximizes the life of machine parts by reducing the force to the machine components.

Vibration System

Hang vibration table could bear violent vibration without any damage to rack. And vibration table placed on rubber spring could greatly reduce noise around 10~15 decibel and avoid damage to machine.

Vibration table consists with Static and dynamic table,When vibration starts,dynamic table vibrate,static table remain static.The structure is designed to ensure the amplitude of the vibration table.

The vertical vibration made by eccentric vibration shaft will guarantee the quality and density of concrete products.

Hydraulic system

The double vane pump is world famous brand "Yuken" to coordinate proportional valve,the vibration amplitude and frequency could be adjusted freely. With proportional valve, the flow and pressure of each movement could be adjusted on touch panel according to actual situation, even to set stage speed in the same movement, making machine running quickly and without impact.

PLC Control system

The PLC controls each production procedures with Siemens touch panel & Siemens PLC or Mitisubishi PLC, both in English and Chinese. The electrical components of the control system use well-known international brands to ensure the stability of the control system, and parameters of the system can be modified from the touch screen. Remote service and Internet of Things(IoT) technology in our control system allows our customer could resolve the problem in shortest time,the parameter in touch screen can be set from Mobile phone by our technician in our office in China.

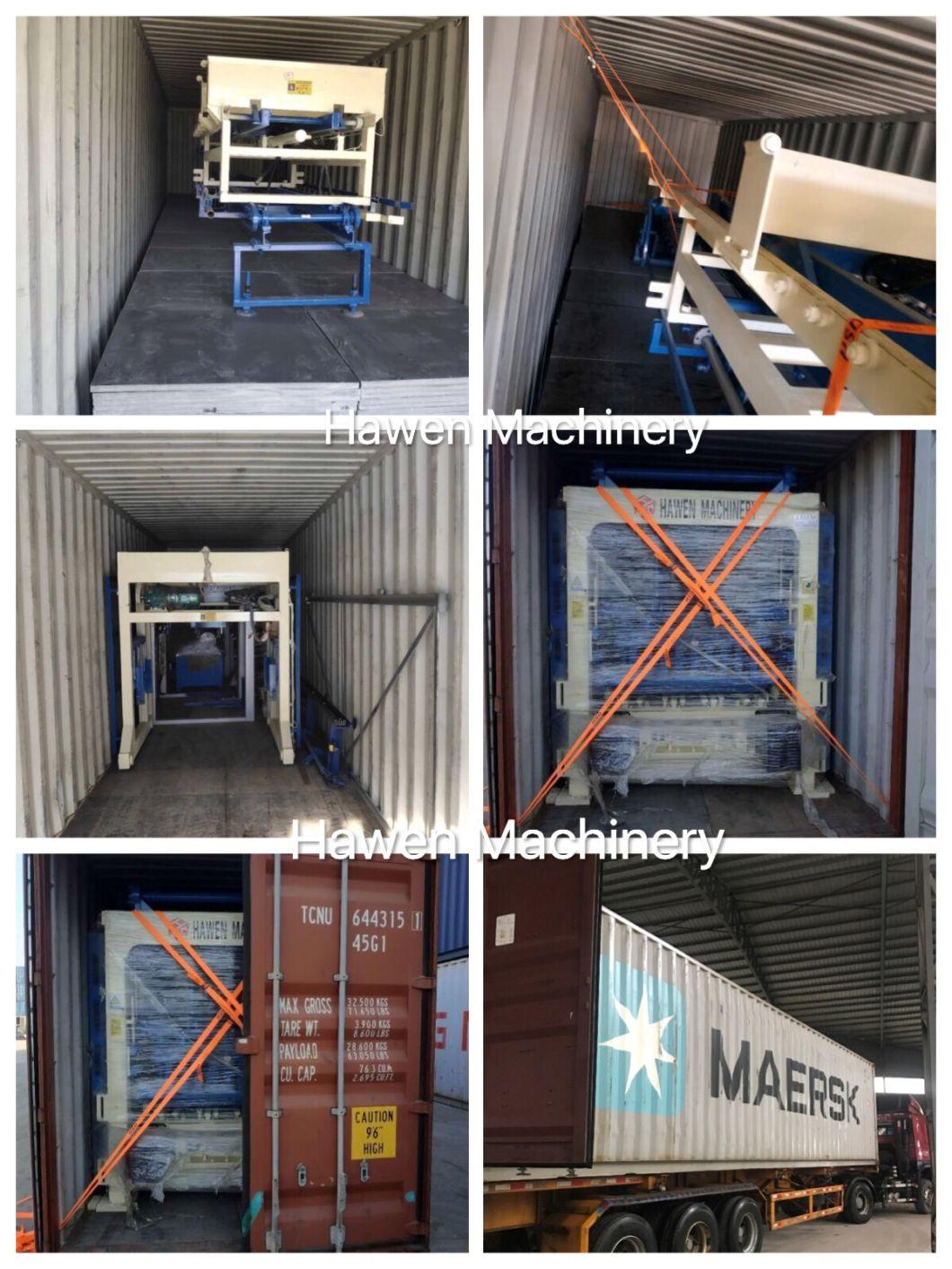

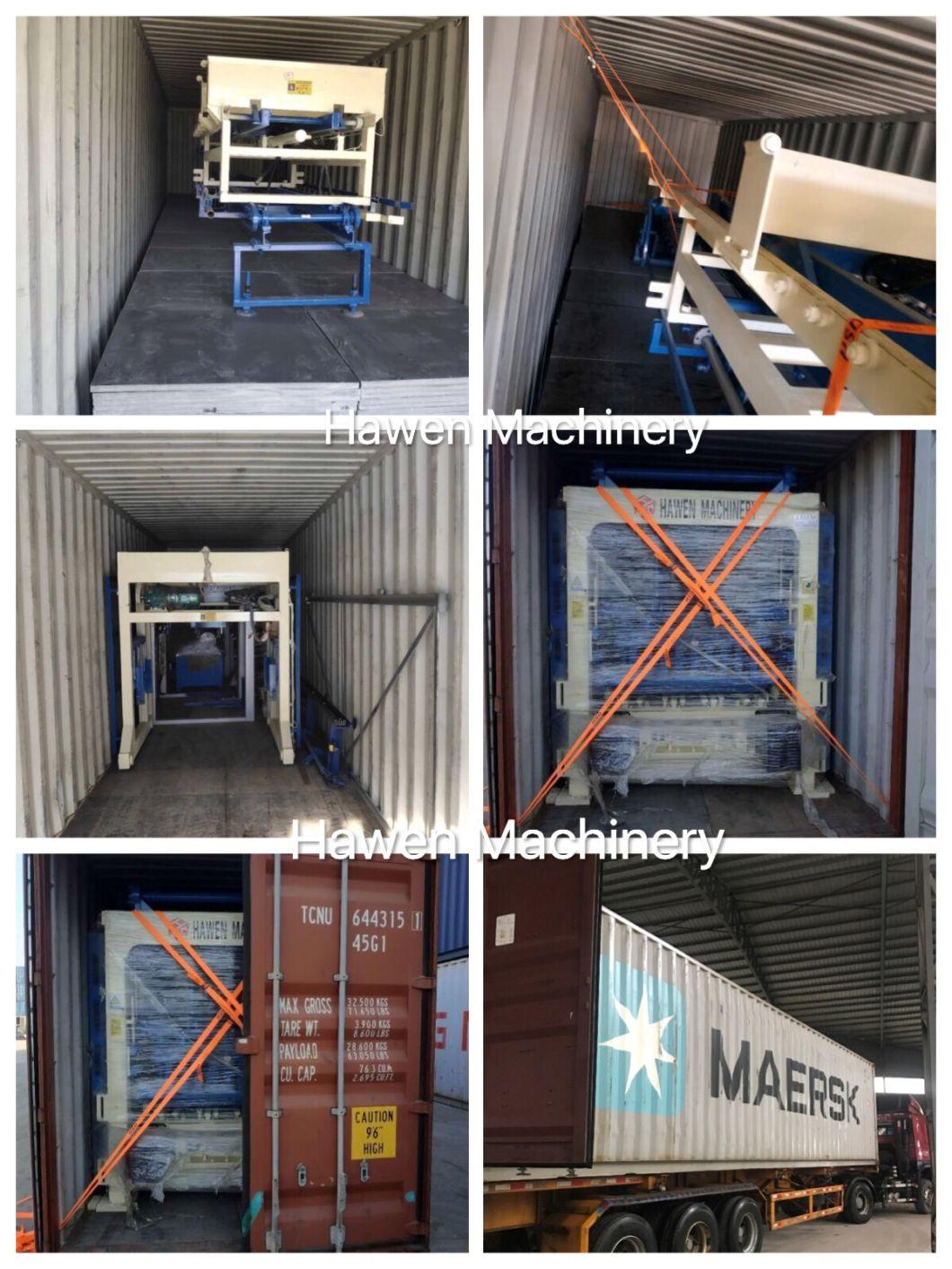

Packing and shipment

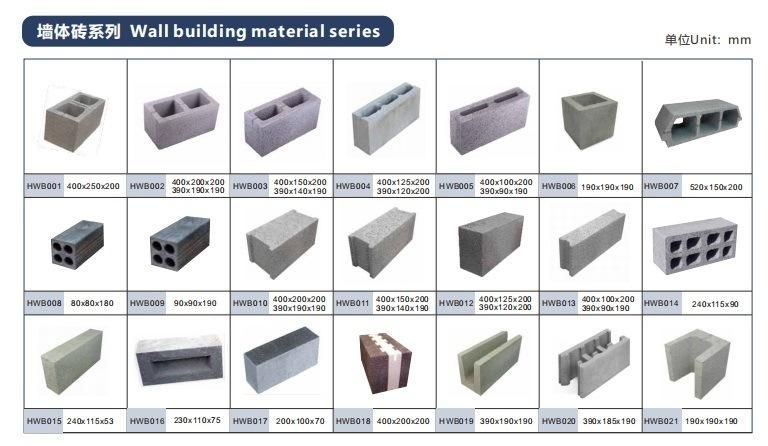

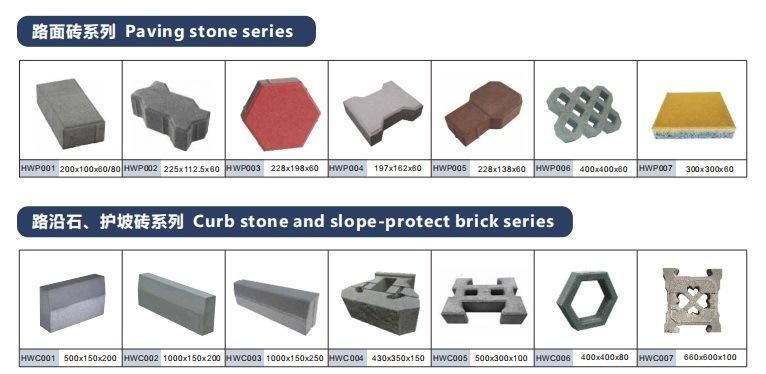

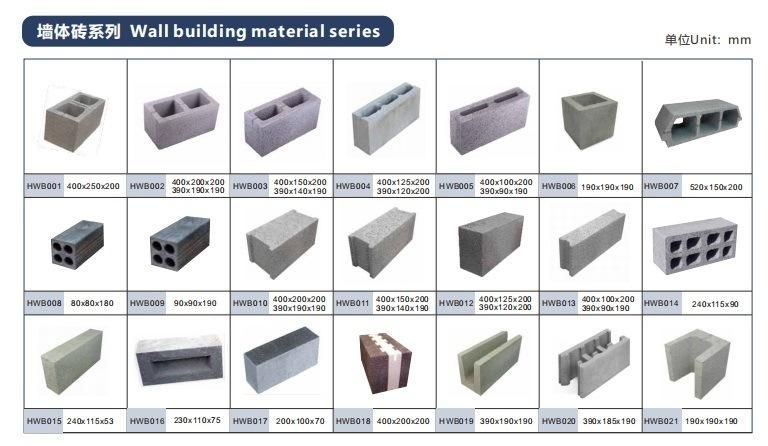

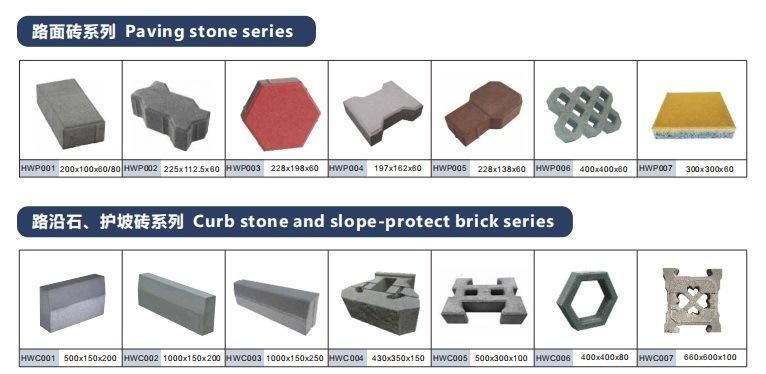

Brick and Block sample:

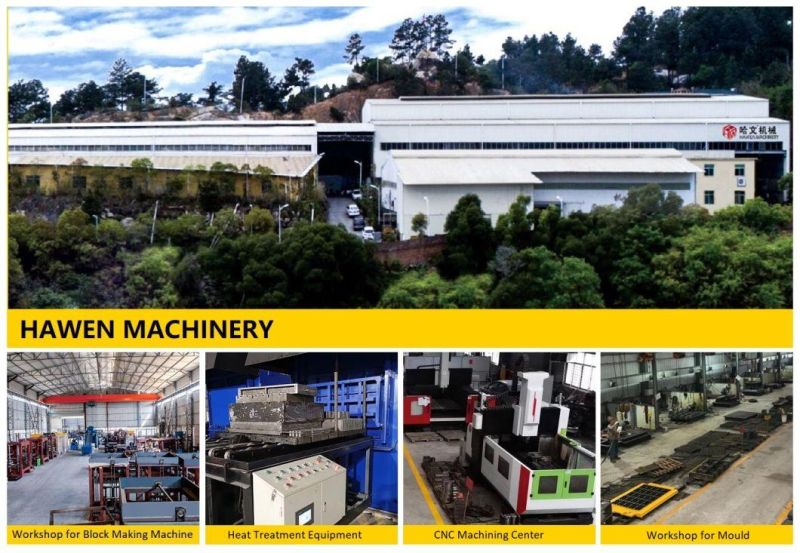

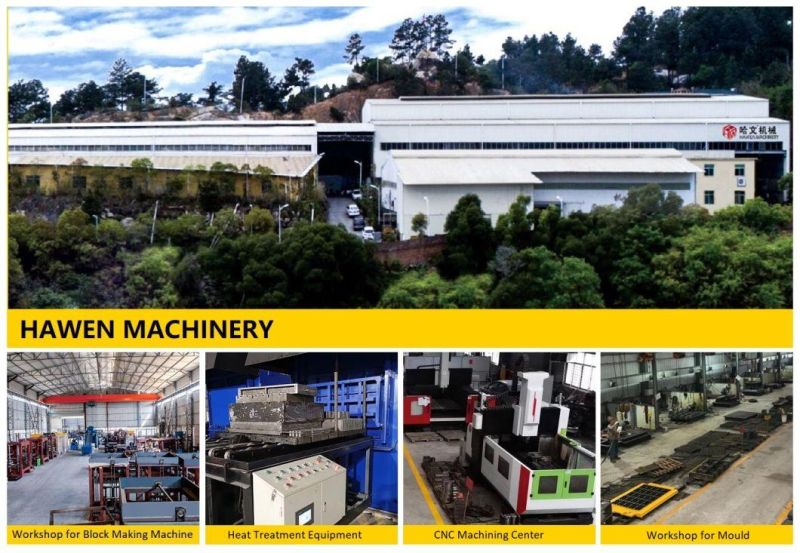

Our factory:

Our Service:

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.

Our certification:

Brief Introduction

HWG-1000 block making machine,using servo motor vibration, it is more energy saving and the response speed is faster. With imported vane pump and hydraulic valve make the equipment run stably and the forming speed faster, which can greatly reduce the cost of brick making.The special vibration and feeding system of this machine can meet the demand of different blocks production for customers,like Hollow block, Solid block,grass-planting paver, curb stones, slope-protect bricks, inter-lock blocks and so on.

Advantage of HAWEN Block Making Machine

Servo motor vibration technology

Through the use of Servo motors, smooth out the machine cycle resulting in the production of higher quality concrete products. Equally important, it extends the life of machine and mold parts.

It precisely control the acceleration and deceleration of the bull gear maximizes the life of machine parts by reducing the force to the machine components.

Vibration System

Hang vibration table could bear violent vibration without any damage to rack. And vibration table placed on rubber spring could greatly reduce noise around 10~15 decibel and avoid damage to machine.

Vibration table consists with Static and dynamic table,When vibration starts,dynamic table vibrate,static table remain static.The structure is designed to ensure the amplitude of the vibration table.

The vertical vibration made by eccentric vibration shaft will guarantee the quality and density of concrete products.

Hydraulic system

The double vane pump is world famous brand "Yuken" to coordinate proportional valve,the vibration amplitude and frequency could be adjusted freely. With proportional valve, the flow and pressure of each movement could be adjusted on touch panel according to actual situation, even to set stage speed in the same movement, making machine running quickly and without impact.

PLC Control system

The PLC controls each production procedures with Siemens touch panel & Siemens PLC or Mitisubishi PLC, both in English and Chinese. The electrical components of the control system use well-known international brands to ensure the stability of the control system, and parameters of the system can be modified from the touch screen. Remote service and Internet of Things(IoT) technology in our control system allows our customer could resolve the problem in shortest time,the parameter in touch screen can be set from Mobile phone by our technician in our office in China.

Packing and shipment

Brick and Block sample:

Our factory:

Our Service:

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

On-sale service support

Assist clients to finish the factory planning,like foundation construction, power preparation,water pool preparation,etc. Before delivery equipment to customers, complete debugging and checking,our machine will do hot testing in workshop with material. Provide a full instruction manual for the block making machine. Provide technical guidance for the installation , including installation advice and electrical connection.

After-sale service support

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.Our certification: