Galvanized Roof Sheet Roll Forming Machine for Africa Market

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, ISO, CE, SGS

- Condition:New

Base Info

- Model NO.:roof forming machine

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Hydraulic Pressure

- Name:Roof Forming Machine

- Control System:PLC

- Rolller:High Grade 45# Steel

- Froming Steps:13

- Hydraulic Pump Station:4kw

- Motor Power:4kw

- Chain:1inch

- Cutter:Cr12

- Middle Plate:16mm

- Products:Roof Forming Machine

- Transport Package:Nude, Covered with Plastic Film

- Specification:CE, SGS

- Trademark:DIXIN

- Origin:Botou, Hebei, China

- HS Code:84552210

- Production Capacity:30 Sets,Month

Description

Basic Info.

Model NO. roof forming machine Customized Customized Usage Roof, Wall Transmission Method Hydraulic Pressure Name Roof Forming Machine Control System PLC Rolller High Grade 45# Steel Froming Steps 13 Hydraulic Pump Station 4kw Motor Power 4kw Chain 1inch Cutter Cr12 Middle Plate 16mm Products Roof Forming Machine Transport Package Nude, Covered with Plastic Film Specification CE, SGS Trademark DIXIN Origin Botou, Hebei, China HS Code 84552210 Production Capacity 30 Sets/MonthProduct Description

Galvanized Roof Sheet Roll Forming Machine for Africa marketWhy choose Dixin Roll forming machine ?

1. Free technical support and free accessories supply.

2. Engineer available to service machinery overseas.

3. One year warranty is provided.

4. Long life technical guidance for free.

5. We always offer technical support, quick response, all your inquire will be replied in 24 hours.

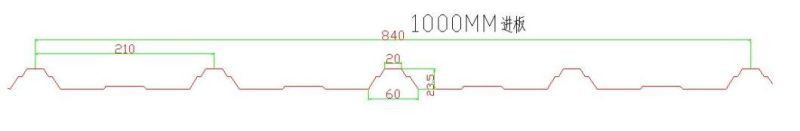

1.Panel drawing for your reference ,coil width usually 914mm/1000mm/1200mm/1220mm/1250mm/1450mm,we can produce the machine according to your request.

2.Some machine pictures for your reference.

3. Work flow of roof forming machine:

Decoiling the sheet----sheet guilding----film covering(option)----roll forming----PLC controlling----hydraulic cutting----receiving the finished panel

4.Technique parameters

Above all the parameters can be changed exactly according to customer's requirements.

| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 2.Material thickness | 0.3-0.8mm |

| 3.Feeding width: | 1000mm |

| 4.Effective width | 840mm |

| 5.Main motor power | 4kw |

| 6.hydraulic pump power | 4kw |

| 7. Shaft diameter | 75mm |

| 8.Forming steps | 13steps |

| 9.Main frame | 300H Steel frame |

| 10. Side plate thickness | 16mm |

| 11.Roller material | 45# forged steel, with hard chrome plating |

| 12.Control systerm | PLC control system with touch screen |

| 13.Cutting blade material | Cr12 |

| 14.Working speed | About 10-12m/min |

| 15. Transmission way | 1 inch chain drive |

| 16. Machine size (mm) | About 6800*1500*1400mm |

| 17. Machine weight | About 2.5ton |

| 18.Power supply | 380v,3phase,50hz or accodring to customer request |

| No. | Name | Unit | Qty |

| 1 | Main forming machine | set | 1 |

| 2 | PLC control system | set | 1 |

| 3 | Hydraulic pump station | set | 1 |

| 4 | Cutting system | set | 1 |

| 5 | Electric motor | set | 1 |

| 6 | 5 ton Manual decoiler | set | 1 |

| 7 | Some spare parts |

6.Packing and shipping

1.one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

7 about our materials

We choose the best raw materials for our machines, Because every customer is not easy, we must provide high quality machines.

8.FAQ:

Q1. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspectthe machine well and before delivery. Of course your payment terms are acceptable.After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after -sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across theworld.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand com-ponents.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of anymachine.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beiing airport, By high speed train From Beiing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

If you want to know about more details about our machine ,Please Contact Bella Mobile

Quality first, service first, your satisfaction is the driving force of our progress.(I can provide you a top quality with a good price )