Vertical Insulating Glass Unit Sealing Machine

Shandong Truetec Machinery Co., Ltd.- Condition:New

- Certification:CE

- Automatic Grade:Automatic

- CNC or Not:CNC

- Voltage:380V

- Product Name:Vertical Insulating Glass Unit Sealing Machine

Base Info

- Model NO.:JYT-2000

- Input Power:13kw

- Air Pressure:0.5-0.8MPa

- Max. Processing Glass Size:2000*2500mm

- Min. Processing Glass Size:300*450mm

- Working Direction:Right to Left or Left to Right

- Working Pressure:32MPa

- Transfer Speed:5-40m,Min

- Machine Dimension:8800*1500*3100mm

- Weight:2500kg

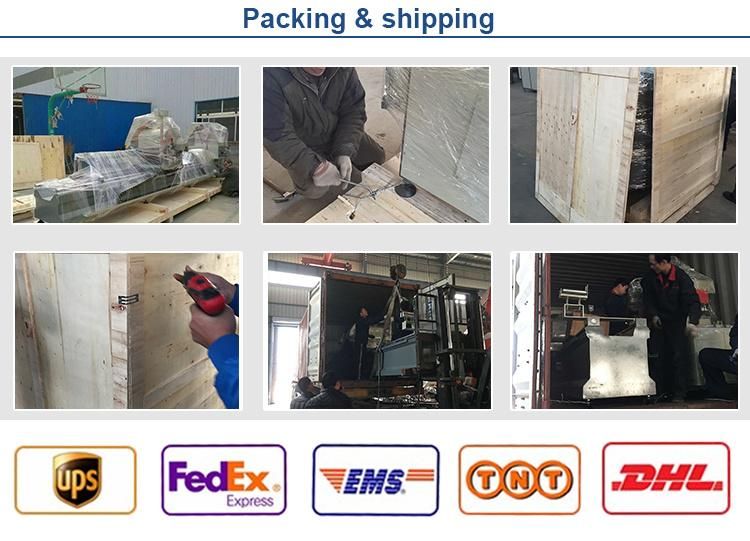

- Transport Package:Standard

- Specification:JYT-2000

- Trademark:Truepro

- Origin:China

- HS Code:846490

- Production Capacity:200 Sets,Year

Description

Basic Info.

Model NO. JYT-2000 Input Power 13kw Air Pressure 0.5-0.8MPa Max. Processing Glass Size 2000*2500mm Min. Processing Glass Size 300*450mm Working Direction Right to Left or Left to Right Working Pressure 32MPa Transfer Speed 5-40m/Min Machine Dimension 8800*1500*3100mm Weight 2500kg Transport Package Standard Specification JYT-2000 Trademark Truepro Origin China HS Code 846490 Production Capacity 200 Sets/YearProduct Description

Vertical insulating glass unit sealing machine

Machine feature:

1.The machine is suitable for glass deep processing enterprise ,high automation, Reduce labor intensity, save manpower, improve production efficiency

2. Whole machine adopt man-machine touch screen interface, with memory function .

3.After coating sealant ,the glass edge and corner is full without air bubbles , smooth surface, no need to pare the corner

4. Using one/two sets of independent sealant supply system , one/two kinds of sealants switch fast ,in one-button operation easily (Model B),save time to change sealant .

5.The width of machine is 1.5m ,small floor area, save space

6. The sections is one production line, it can prestore three pcs glass to improve the efficiency effectively

7.The smallest insulating glass size can be processed is 300*450mm

8.Equipped with anti blocking device in the mixer, easy to clean

9. Servo control system adopts world famous brand (Japan YASKAWA ), the performance is stable , counting speed is fast ,sealant output with high precision ,surface with high smoothness .

10. Shaft transmission to make the glass being transferred smoothly with accurate positioning.

11. Special V type transmission belt to avoid the sealant sticking on the belt, ensure the glass edge clean , V type Block is changeable

12. The key components are produced with high standardization and high precision, ensure the machine can be used with long-term stability

13.Suitable for triple glazing .

14.Conveying wheel on backboard adopts embedded wheel ,to make sure the glass be transported smoothly

15.Equipped with high speed positioning function ,glass can be located accurately when transport fast .

Parameter:

| Product model | JYT-2000 |

| Power supply | 380V/50HZ |

| Power | 13kw |

| Air supply | 0.6-0.8Mpa |

| Max. glass size | 2000*2500mm |

| Min. glass size | 300*450mm |

| Conveyor speed | 5-40m/min |

| Dimension | 8800*1500*3100mm |

| Weight | 2500kg |

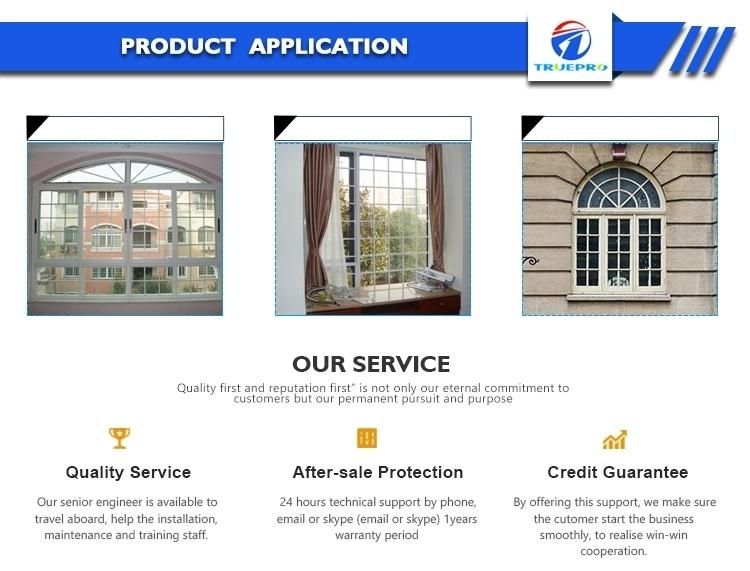

Jinan Truepro is a manufacturer of window machine, insulating glass processing machine and curtain wall machine with

well-equipped testing equipment and strong technical force. With a wide range, good quality, reasonable prices and stylish

designs, our products are extensively used in building trade and other industries. Hope we can cooperate with you.

We believe that "IT'S THE BEST THAT FITS MOST."

Every machine could be customized to meet your special requirement.

1. When can we arrange shippment?

We usually arrange shippment within 15 days after getting deopsit,

but customized machines should be more than 25 days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can dispatch our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.

All of our engineers have passport.

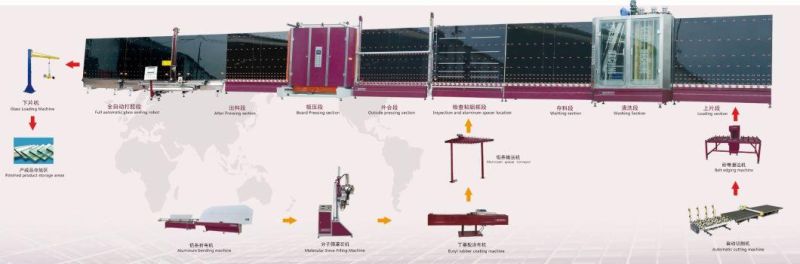

4. Insulating glass production line