Low Price Limestone Calcine Rotary Kiln Plant

Henan Zhengzhou Mining Machinery Co., Ltd.- Application:Construction

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Installation:Under Our Engineer′s Guide

- Training:on Site

Base Info

- Model NO.:Various Model

- Certificate:ISO9001, ISO14000, Ce

- Color:Can Be Customerized

- After Sale Service:for The Whole Using Life

- Spare Parts:Supply for The Whole Year Freely

- Capacity:1-2500tpd

- Testing:We Offer

- Experience:More Than 50 Years

- Warranty:One Year

- Transport Package:by Bulks, Spare Parts Are Packed in Wooden Box

- Specification:ISO9001, ISO14000, CE

- Trademark:ZK

- Origin:Henan, China (Mainland)

- Production Capacity:100-2500tpd

Description

Basic Info.

Model NO. Various Model Certificate ISO9001, ISO14000, Ce Color Can Be Customerized After Sale Service for The Whole Using Life Spare Parts Supply for The Whole Year Freely Capacity 1-2500tpd Testing We Offer Experience More Than 50 Years Warranty One Year Transport Package by Bulks, Spare Parts Are Packed in Wooden Box Specification ISO9001, ISO14000, CE Trademark ZK Origin Henan, China (Mainland) Production Capacity 100-2500tpdProduct Description

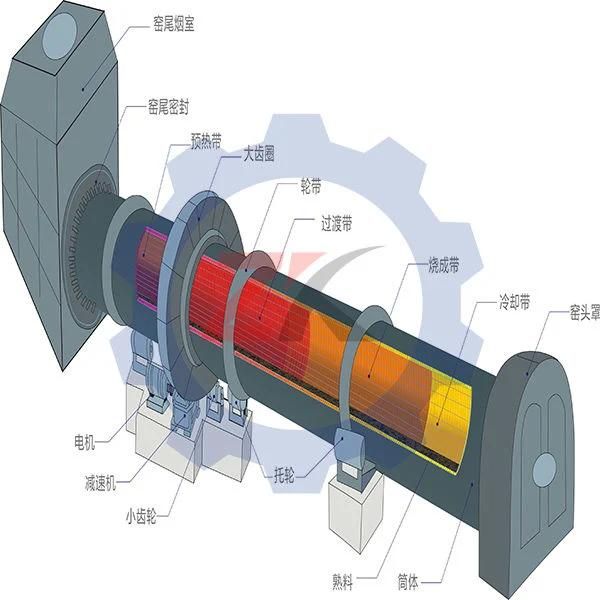

Low Price Limestone Calcine Rotary Kiln PlantRotary Kiln belongs to building material equipment, according to different materials, which can be divided into cement kiln, metallurgy chemical kiln and lime kiln. Cement kiln is used for making cement clinker and there are dry and wet methods to make cement clinker. Metallurgy chemical kiln is widely used for magnetic roasting of poor iron ore and oxidizing roasting of chrome and nickel in the steel factory; backing high-alumina mine in the refractory material factory; baking chamotte and alumina in the aluminum factory and baking chrome ore and chrome powder in the chemical plant. The Lime Kiln is used for roasting active lime in steel works and ferroalloy plants and light roasting dolomite.

Features of rotary kiln:

1) Professional design

2) 50 years experience

3) PC control system

4) Environmental

Project includes the following sections:

1)Screening of raw materials, the feeding system

2)Preheater system

3)Rotary kiln calcined system

4)Burning system

5)Cooling system

6)Fuel gas treatment system

7)Coal preparation system

5)Lime powder processing and storage transportation systems

The energy-saving rotary kiln:

A) There is a vertical preheater in the end of rotary kiln, make the best of the high temperature combustion gas to preheating the materials, so that materials in the preheater was partially decomposed, so that System production capacity increased by 40%, and thermal efficiency increased by 30% comparing the traditional process.

B) Regarding the cooling system of the end high active lime product, We apply the modern advanced technology of the new type vertical cooling machine, The device is new fourth generation reference to the foreign upright cooler specially designed products in late nineties, The device machine running smoothly, with a strong quenching effect, the cooling effect is obvious, the increased activities of the lime is extremely beneficial

C) Flue gas treatment system configuration and high efficiency heat exchanger bag filter, replacing the traditional electrostatic precipitator, the measures will not only reduce the use of highly efficient heat exchanger preheater exhaust gas temperature, increase air temperature, to reduce the volume of the combustion gas, bag dust collector replaced the electrostatic precipitator.

Our service:

1. Select excellent installation team or installation service personnel for you;

2. Provide you with operating and training services;

3. Help with the equipment commissioning, and solve problems in trial operation;

4. Check and acceptance service for single equipment or a whole production line;

5. Service items including follow-up visit, customer satisfaction surveys and so on;

6. Timely provide you with necessary accessories after acceptance;

7. Provide you with warranty services of repair, replacement and refund if conditions are fulfilled.

8. Help you solve other problems.