Four Cutters End Millingmachines for Aluminium Window Door Profile

Shandong Truetec Machinery Co., Ltd.- Condition:New

- Certification:ISO, CE

- Automatic Grade:Semi-Automatic

- CNC or Not:not CNC

- Voltage:380V

- Product Name:Four Cutters End Millingmachines for Aluminium

Base Info

- Model NO.:CLXDB-250B

- Cutting Motor Power:8.8kw

- Motor Rotary Speed:2800r,Min

- Air Pressure:0.5-0.8MPa

- Spindle Diameter:Φ32mm

- Diameter of Milling Cutter:Φ250mm

- Saw Blade Specification:Φ305

- Worktable Journey:0-1560mm

- Worktable Dimension:530*320mm

- Motor Adjustable Journey:0-85mm

- Max. Processing Tenoningsize:40mm

- Color:Gray or as Requirement

- Keywprd:End Milling Machine Operation

- Transport Package:Simple Stretch Film or Plywood

- Trademark:TRUETEC

- Origin:Shandong China

- Production Capacity:20 Sets Per Month

Description

Basic Info.

Model NO. CLXDB-250B Cutting Motor Power 8.8kw Motor Rotary Speed 2800r/Min Air Pressure 0.5-0.8MPa Spindle Diameter Φ32mm Diameter of Milling Cutter Φ250mm Saw Blade Specification Φ305 Worktable Journey 0-1560mm Worktable Dimension 530*320mm Motor Adjustable Journey 0-85mm Max. Processing Tenoningsize 40mm Color Gray or as Requirement Keywprd End Milling Machine Operation Transport Package Simple Stretch Film or Plywood Trademark TRUETEC Origin Shandong China Production Capacity 20 Sets Per MonthProduct Description

Four cutters end millingmachines for aluminium window door profile Equipment Advantages

Equipment Advantages- Used for milling the aluminum mullion/transom and reinforced mullion.

- Large milling capacity, multi-pieces profile milling in one cycle.

- Universal milling blades can be adjusted in up/down, left/right directions to fit for different processing requirement and ensure the efficient working.

- Suitable for the reinforced mullion in one cutting/milling cycle.

- Large diameter tools with high and stable milling speed for guarantee the working quality.

| Model | CLXDB-250B |

| Input power | 8.8kw |

| Power supply | 380V 50Hz |

| Motor rotary speed | 2800r/min |

| Operation air pressure | 0.5-0.8MPa |

| Spindle diameter | Φ32mm |

| Saw blade specification | Φ305 |

| Diameter of milling cutter | Φ250mm |

| Worktable journey | 0-1560mm |

| Worktable dimension | 530*320mm |

| Motor adjustable journey | 0-85mm |

| Max. processing tenoningsize | 40mm |

| Cutting surface roughness | 12.5um |

| Overall dimension | 3000*970*1670 |

| Weight | 650kg |

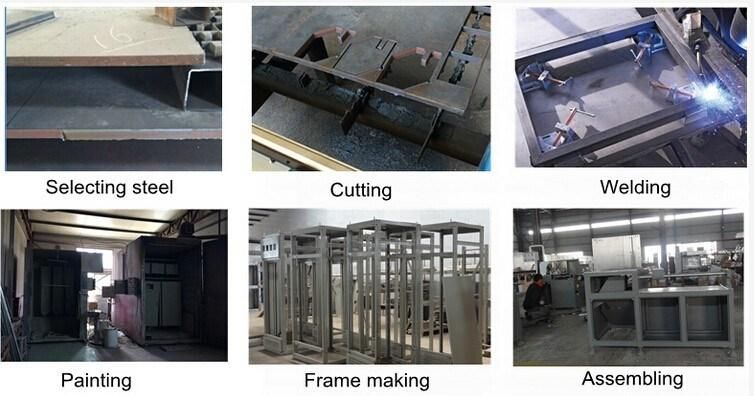

Machines Details

Machine processing

We work with everything from raw material to final machine, could guarantee machine quality from each step. select each part carefully, we are strive to quality first when machine production and test each machine before delivery.

We will provide the best machine for you.

Packaging&Shipping

Our Services

Before payment

Free contact for the most suitable machine

Free professional design for each customer especially.

After sale service

24 hours technical support by phone, email or skype (email or skype) .

1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Payment

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union or Paypal.

Our Company

Welcome To Visit

Our company is a manufacturer of window machine, insulating glass processing machine and curtain wall machine with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in building trade and other industries. Hope we can cooperate with you.

Our Exhibition

FAQ

1. When can we arrange shippment?

We usually arrange shippment within 25 days after getting deopsit,

but customized machines should be more than 25 days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.