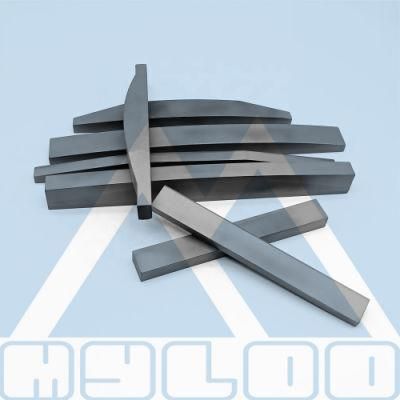

Cemented Tungsten Carbide Bars for VSI Crusher Rotor Tips

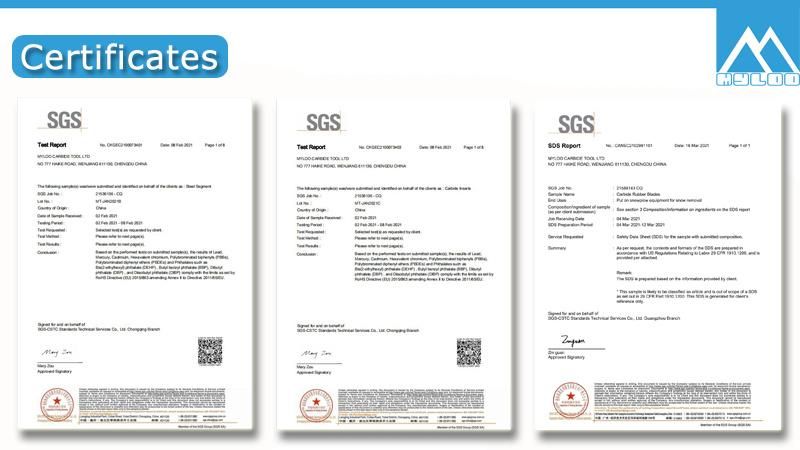

Myloo Carbide Tool Ltd.- After-sales Service:Online or Site

- Hardness:90.5 - 91.0hra

- S.T.R.:1800 - 2000MPa

- Density:14.90g,cm3

- Grain Size:1.0 - 1.6μm

- Usage:Artificial Sand Making

Base Info

- Model NO.:standard

- Experience:18 Years

- Custom-Make:Supported

- Types:a,B,C,D,E Shapes or Customized

- Transport Package:Standard

- Specification:MT6Z

- Trademark:Myloo

- Origin:Zigong, China

- HS Code:820900

- Production Capacity:400-500tons,Year

Description

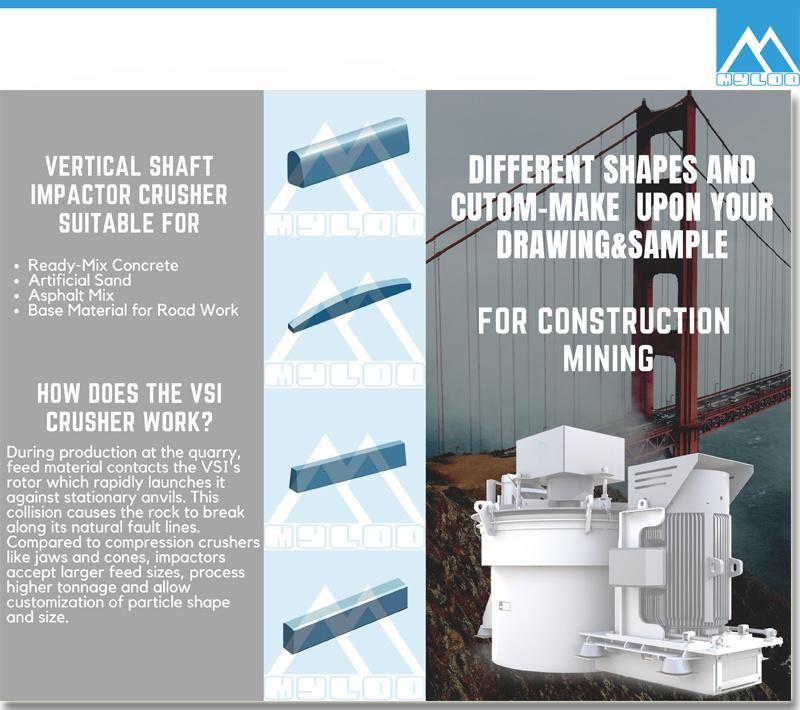

The Ultimate Crushing Solution

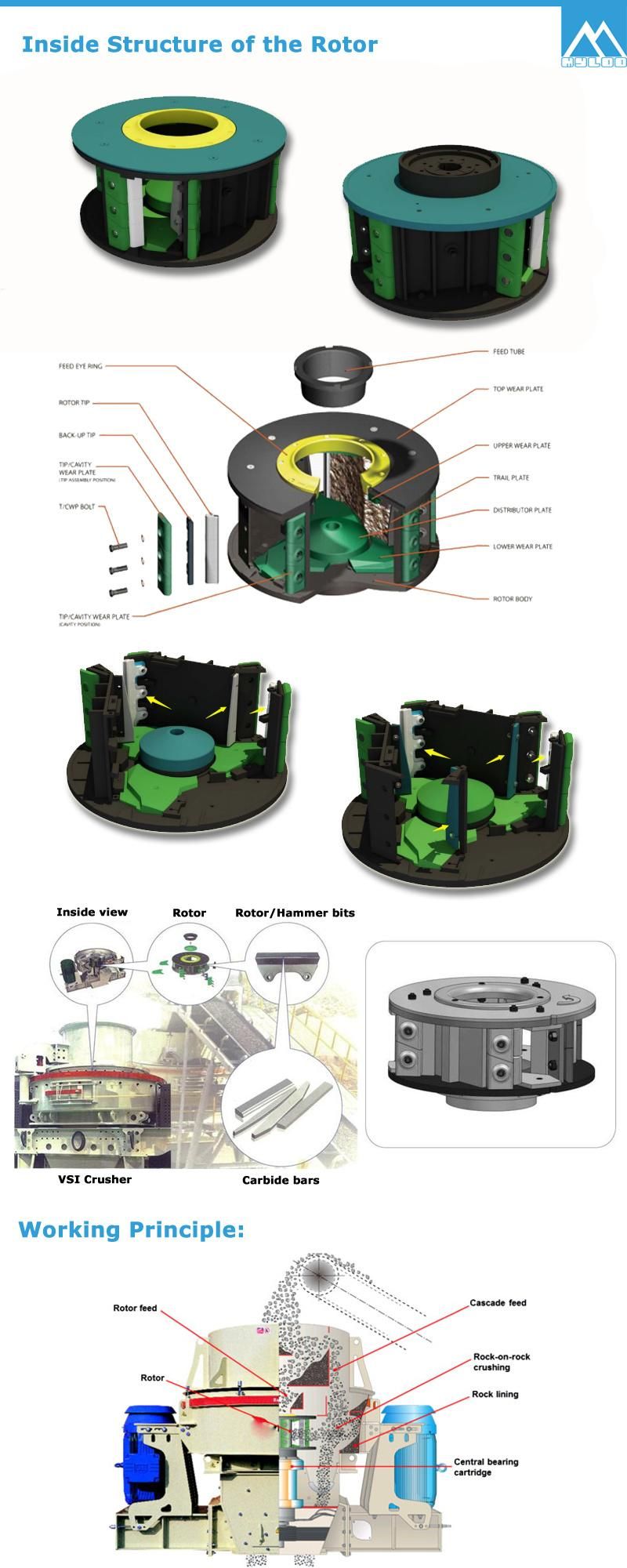

VSI Crusher are unique due to its crushing process. Whereas most other type of crusher use metallic parts to

crush, VSI uses the rock fed into the machine to crush itself. This crushing process produces the best shaped

aggregates. The high velocity impact crushing achieved in VSI improves the shape of stone, reducing product

moisture and thus easing the screening operations. With rock-on-rock crushing action there is advantage of

cost savings, durability and unmatched performance in variety of crushing tasks.

We provide carbide bar well welded rotor bits as a set of wear part to make sure overall quality is

superior to most competitors.

Q&A:

1. Why You Say Your Tungsten Carbide Bars Have Much Better Performance?

-Coarse enough of grain size to be favorable for welding, especially in cold weather.

- Lower Cobalt without broken, longer wear-resistance.

We never stop finding better grade with much longer wear-resistance to save clients' cost. Now we are testing

new grade with coarse grain size for Europe market, it works well. Also we are making another 3 kinds of new

grade to test and compare with current grade. If it goes well, next step we will try to test it for America market first.

2.How You Control the Quality of The Carbide Bars?

-Much strict control on scrap carbide to ensure stable quality of carbide powder.

All is from qualified carbide rods with grain size 0.8-1.0um, like end mill, reamer, drills. Other carbide

manufacturers usually use carbide drill bits or anvil with grain size 1.2/1.6/2.0 mixed.

-Our special creative sintering process to ensure uniform grain size 2.4um.

Carbide manufacturers usually sinter it by Intermediate Frequency Furnace with temperature 1500ºC, that the

heat-difference can be 70-80ºC causing non-uniform grain size. We use Vacuum Sintering Furnace with "secret"

temperature without heat-difference to ensure uniform grain size 2.4um.

3.Do You Accept OEM&ODM?

Yes, for sure, we can cutomize the grade and shape upon your drawings or samples. Such as, make the grain coarse or add

more cobalt to increase its hardness. Make balance on hardness and toughness.