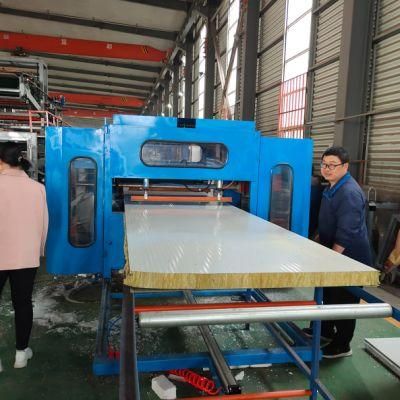

Cold Room Sandwich Panel Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Power Source:Electric

- Screw Design:Double-Screw

Base Info

- Model NO.:Sandwich Panel Roll Forming Machine

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Color:Blue

- Chain:1 Inch

- Forming Steps:23

- Roller:High Grade 45# Steel

- Shaft:75mm

- Material:Galvanized,Aluminum,Color Steel Sheet

- Thickness:0.3-0.8mm

- Middle Plate:14mm

- Hydraulic System:PLC Computer

- Electric Motor:4kw

- Transport Package:Nude, Covered with Plastic Film

- Specification:CE, SGS

- Trademark:DIXIN

- Origin:Botou, Hebei, China

- HS Code:845522

- Production Capacity:30 Sets,Month

Description

4. Advantage of DIXIN roll forming machine

Components of the whole production line:

| No. | Name | Parameters |

| 1 | Composite De-coiler | 1 |

| 2 | Main Machine For forming machine | 1 |

| 3 | Main Machine For Compositing | 1 |

| 4 | Control System(PLC) | 1 |

| 5 | Cutting System | 1 |

| 6 | Run out table |

1. Decoiler

(1)Inner Diameter: Φ508 - Φ610 mm

(2)Out Diameter: 1250mm

(3)Max. Loading Capacity: 5000 kgs

(4)Type:manual

2. Roof sheet machine (double layer):

3.Glue section

a.Glue section

(1) Numbers of pump: 4 sets (top and bottom each 2)

(2) Driven power: 0.37KW

(3) Flow volume of glue: 0~0.4 kg per pump

(4) Type of flow volume control: Change frequency

(5) Scale of glue: (white): (Black) 1.5

(6)Gule name: PUA and PUB

(7)Speed of spreading:80times/min

(8)Driven power:0.5KW x 3

b.Apply Guard Film:

(1) Type of apply guard film: Automatic

c. Grooving formingdevice

(1) Grooving: according to the design requirement

(2) Depth of groove: 0.5~1.0mm

d. EPS grooving cutter and EPSwaste collector

(1) Type of cutting: electrical heat cutting

(2) Numbers of heater: 3

(3) Power of heater: 2.5kw×6

(4) Driven power:0.75KW

(5) Type of collecting: Vacuum

(6) Driven power:2.2kw

e. Sandwich panel cutting device

(1)Material:EPS

(2) Type of cutting:shearing cutter

(3) Driven power: 1.5kw×2

(4) Thickness of panel: 40-300mm

(5) Length of panel: 1200~30000mm

(6) Movement of cutter:1800mm(cylinder distance)

(7) Type of operating:touch screen

f. Electrical system:

(1)Electrical Voltage:380V/3Ph/50Hz

(2)Type of controlling: PLC (Delta,Taiwan)

(3) Encorder: Omron

5. Want a free quotation for make budget?Just send inquiry to me now!

6. We are your reliable partner!

We always do the best to make our machine perfect in every detail part.

Any pics or videos about machine, we can provide you.

7. Payment terms

30% T/T as the deposit when contract signed, 70% balanced before shipping.

Our services:

1. we can produce the special machine,send your drawing to us,we can design for you.

2. if you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

3. we provide a one year warranty and lifelong technical support, we can send our technicians to you to give you on-site training.

The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of US50.

4. engineers available to service machinery overseas.

5. if you come to visit our factory,we can book the room for you, car pick up to send.