Qt4-15 Concrete Brick Making Machine\ Automatic Brick Machine\Block Machine\Construction Equipment

Linyi Duyue Import and Export Co., Ltd.- Certification:CE, ISO, Son

- Customized:Customized

Base Info

- Model NO.:QT4-15

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Cycle:15s

- Pallets Size:900X550X30mm

- Vibration Force:50kn

- Rate Pressure:16MPa

- Total Weight:6500kg

- Vibration:4000-4800,Minute

- Water Consumption:5-6t

- Moldels of Mixer:Js500

- Transport Package:Container

- Specification:3700*1500*2600mm

- Trademark:DUYUE

- Origin:Linyi City, China

- HS Code:8474802000

- Production Capacity:200sets,Year

- Package size per unit product:370.00cm * 200.00cm * 270.00cm

- Gross weight per unit product:5000.000kg

Description

Basic Info.

Model NO. QT4-15 Automatic Grade Automatic Type Hydraulic Shock After-Sales Service Provided Engineers Available to Service Machinery Overseas Cycle 15s Pallets Size 900X550X30mm Vibration Force 50kn Rate Pressure 16MPa Total Weight 6500kg Vibration 4000-4800/Minute Water Consumption 5-6t Moldels of Mixer Js500 Transport Package Container Specification 3700*1500*2600mm Trademark DUYUE Origin Linyi City, China HS Code 8474802000 Production Capacity 200sets/YearPackaging & Delivery

Package size per unit product 370.00cm * 200.00cm * 270.00cm Gross weight per unit product 5000.000kgProduct Description

Production description

1.Material and welding: all material and spare parts selected according international CE standard, Carbon dioxide protection welding will assure whole line stable running.

2.Control PLC: we select original Mitsubishi PLC combine with independently develop machine control program, assure stable and high-efficiency working status.

3.Switches and motor: Switches will use Japan Omron and France Schneider brand; motor will use Siemens or ABB brand.

4.Hydraulic system: Hydraulic spare parts be ordered according our block machine characteristics from Taiwan. 5.Material feeder: Rotary mixer type material feeding cart, finished products get higher density and strength. 6.Mould: newest heat treatment device assure longer mould life span.

7.Spare part: follow the machine shipment, we supply suitable wearing parts, the after-sale services will be faster.

Main technical parameters

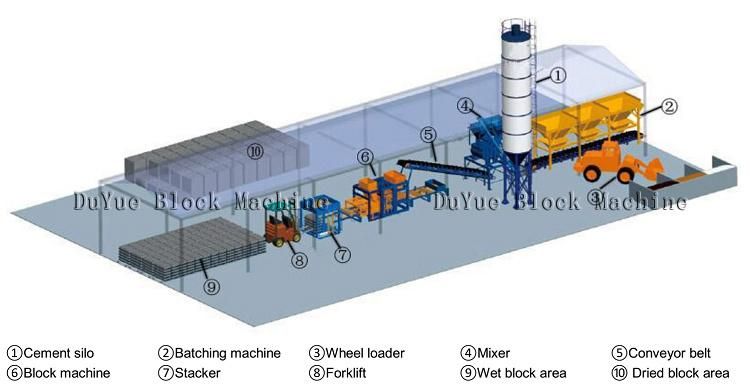

Product details

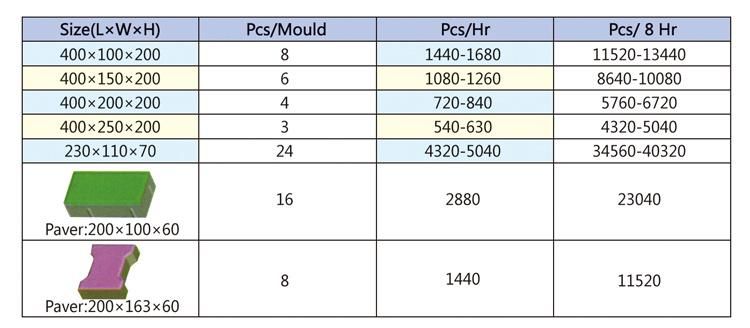

Theoretical production efficiency

Our service

Pre-sale:

(1) Professional suggestions (raw material matching, machine selection, plan.

The condition of building factory, feasibility analysis for brick machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity

And the size of brick).

(3) 24 hours on-line service.

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

Letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate.

(3) offer training to the operator until they are satisfied at clients side.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other.

Duyue Industry Co.,LTD

Please contact with me

Nancy