EPS Sandwich Wall Panel Production Line

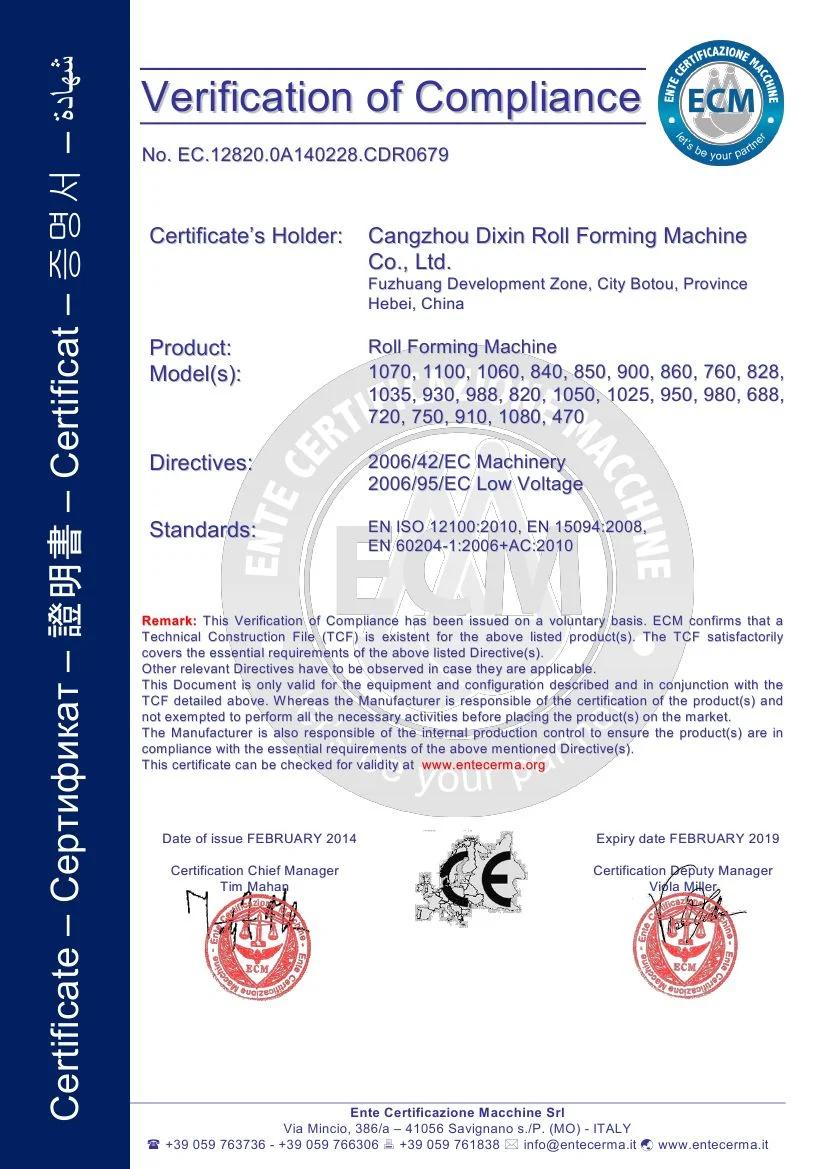

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE

- Condition:New

Base Info

- Model NO.:DX950-1250

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Machinery

- Name:EPS Sandwich Wall Panel Production Line

- Coil Material:Colored Steel Sheet, Aluminium Sheet, Galvanized S

- Thickness of The Plate:0.3-0.8mm

- Width:950-1200mm

- Core Thickness:40-300mm

- Appearance:38000mm × 3600mm × 3300mm

- PLC Control System:Easy to Operate, High Precision and Work Stably

- Total Power:About 25kw

- Speed:1000~4000mm,Min

- Density of EPS Panel:>18kg,Mmm

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX980-1250

- Trademark:DX

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:1 Set Per Month

Description

Basic Info.

Model NO. DX950-1250 Customized Customized Usage Roof, Wall Transmission Method Machinery Name EPS Sandwich Wall Panel Production Line Coil Material Colored Steel Sheet, Aluminium Sheet, Galvanized S Thickness of The Plate 0.3-0.8mm Width 950-1200mm Core Thickness 40-300mm Appearance 38000mm × 3600mm × 3300mm PLC Control System Easy to Operate, High Precision and Work Stably Total Power About 25kw Speed 1000~4000mm/Min Density of EPS Panel >18kg/Mmm Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX980-1250 Trademark DX Origin Botou Hebei China HS Code 845522 Production Capacity 1 Set Per MonthProduct Description

eps sandwich wall panel production line

Rock wool/Foam Sandwich Panel Roll Forming Machine

wall panel EPS"H" (1000-1200mm)

feeding width of upper sheet: 1000/1200mm

feeding width of down sheet: 1000/1200mm

hidden wall panel EPS(950-1150mm)

feeding width of upper sheet: 1000/1200mm

feeding width of down sheet: 1000/1200mm

roof panel EPS lapped tape 980 sandwich panel

feeding width of upper sheet: 1200mm

feeding width of down sheet: 1000

main parameters:

1. Coil material: colored steel sheet, aluminium sheet, galvanized steel sheet

2. Thickness of the plate : 0.3-0.8mm

3. Width: 950-1200mm

4. Core thickness: 40-300mm

5. Appearance: 38000mm × 3600mm × 3300mm

6. PLC control system, easy to operate, high precision and work stably.

7. Total power: about 25KW

8. speed: 1000~4000mm/min

density of EPS panel: >18KG/mmm

material:1000~1200mm × (0.5~0.6mm )rock wool and foam

9. Power :380V,50-60Hz

10. Thickness :50-250mm

11. Annual production: 600,000 square meter

12. Production line weight: 13T

13. Loading requirement 12.5 m * 2m ( 2*40-foot high containers )

14. Payment:30% TT in advance and balance before shipment or L/C

15. Delivery time:30 days ( one month )

16. Quality gurantee:One year gurantee after delivery ( excluding considered natural disasters )

17. Production lines by the supplier free installation,commissioning, personnel transportation costs shall be payed by the supplier including tickets and accommodactions and salary of USD 80 daily!

Our enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc. We can satisfy the different needs of different markets.

Warmly welcome to China to visit our factory and select the machines you need. Our address,Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China.

Any questions, we will reply to you promptly.

WARMLY WELCOME TO OUR NEW FACTORY!

1: How to place order

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2: How to visit our company

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

If any questions, you can call me mobile phone at any times:008618231723279