Steel Wall Panel Trapezoidal Tile Roofing Sheet Making Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, ISO

- Condition:New

Base Info

- Model NO.:REQUEST

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Hydraulic Pressure

- Transport Package:Nude in Container

- Specification:7500*1500*1400mm

- Trademark:dixin

- Origin:Botou, Hebei, China

- HS Code:84552210

- Production Capacity:30 Sets,Month

Description

Basic Info.

Model NO. REQUEST Customized Customized Usage Roof, Wall Transmission Method Hydraulic Pressure Transport Package Nude in Container Specification 7500*1500*1400mm Trademark dixin Origin Botou, Hebei, China HS Code 84552210 Production Capacity 30 Sets/MonthProduct Description

Steel Wall Panel Trapezoidal Tile Roofing Sheet Making Machine1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer's requests.

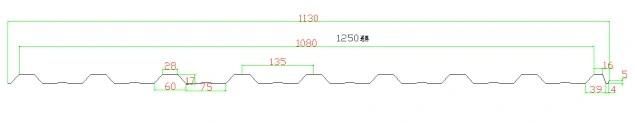

1.Panel drawing according to customers request.

2.some machine pictures for your reference.

3.Equipment detailed parameters:

Metal wall panel trapezoidal tile roofing sheet making machine's technical parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 ton |

| Voltage | 380V/50HZ/3Phase (as customer`s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 20mm/18mm/16mm/14mm/12mm |

| Drive mode | Chain Drice//Gear Drive |

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 13 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Connecting rod shear |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

4.Packing and shipping details

1. Need one 40ft container.

2. Fit for ocean shipping.

3. The main body of the roll forming machine will be naked packing into the container, covered with plastic film.

4. Steel wire fixes the machine into the container, in case of any damage when shaking on the sea.

5. The spare parts will be packed into the carton box.

6. The received goods table put into a carton box.

7. Manual decoiler naked package

5.About our company

Our factory Established in 2001, our factory gets specialized in producing all kinds of roll forming machines such as Corrugated Sheet Roll Forming Machine, IBR Sheets Roll Forming Machine, Glazed Tile Roll Forming Machine, Double Layer Roll Forming Machine, Three Layer Roll Forming Machine, Sandwich Panel Roll Forming Machine, C/Z/U Purline Roll Forming Machine, etc. There are professional engineers and workers to design and produce according to your need.

The machines produced by our factory have been sold worldwide such as Russia , Kazakhstan, England, America, Italy, Australia, Philippines, India, Thailand, Nigeria and Syria, etc. So we are fimiliar with the different needs for different markets.

6.Customer visit

FAQ1. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspectthe machine well and before delivery. Of course your payment terms are acceptable.After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after -sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across theworld.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand com-ponents.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of anymachine.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beiing airport, By high speed train From Beiing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.