Lightweight Cement Precast Concrete Machine for Hollow Core Foam Panel

OYADE (Shandong) Machinery Equipment Co., Ltd.- Warranty:1year

- Product Type:EPS Lightweight Wall Panel Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:ISO

Base Info

- Model NO.:OYD-H3200

- Condition:New

- Customized:Customized

- Mold Car Type:Vertical Mold Car

- Panel Usage:Partition Wall, External Wall, Roof, Floor

- Automation Degree:Full-Automatic and Semi-Automatic

- Installation:Guide by Our Engineers

- Finished Board Size:60-200mm

- Voltage:380V,220V,415V, Adjustable

- Automatic:Full Automatic

- Transport Package:We Will Design EPS Wall Panel Production Line Load

- Specification:capacity: 30000-500000sqm,year

- Trademark:YR

- Origin:Shandong

- HS Code:8474802000

- Production Capacity:80sets,Year

Description

Basic Info.

Model NO. OYD-H3200 Condition New Customized Customized Mold Car Type Vertical Mold Car Panel Usage Partition Wall, External Wall, Roof, Floor Automation Degree Full-Automatic and Semi-Automatic Installation Guide by Our Engineers Finished Board Size 60-200mm Voltage 380V/220V/415V, Adjustable Automatic Full Automatic Transport Package We Will Design EPS Wall Panel Production Line Load Specification capacity: 30000-500000sqm/year Trademark YR Origin Shandong HS Code 8474802000 Production Capacity 80sets/YearProduct Description

Product DescriptionLightweight Cement Precast Concrete Machine for Hollow Core Foam Panel

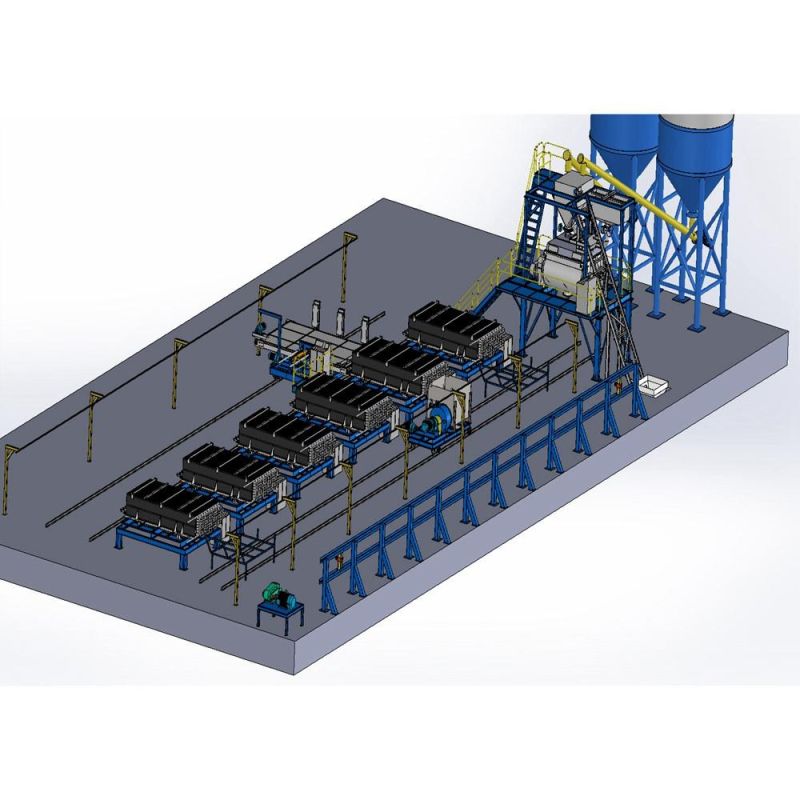

Horizontal Automatic type wall panel production line integrates electronics, hydraulics and mechanics.

Its main production process consists of six parts, namely batching, mixing, automatic grouting, conveying, demoulding and stacking. Two working methods, including manual and automatic recycling are available to select. Its safety and stability can be achieved by the advanced industrial PLC, high-precision hydraulic components and compact mechanical structure.

EPS sandwich panel machine line is in order to adapt to recent development trend of building materials, our company bold innovation design of highly automated production lines, which enables the waste water and materials be reused through elaborate design.

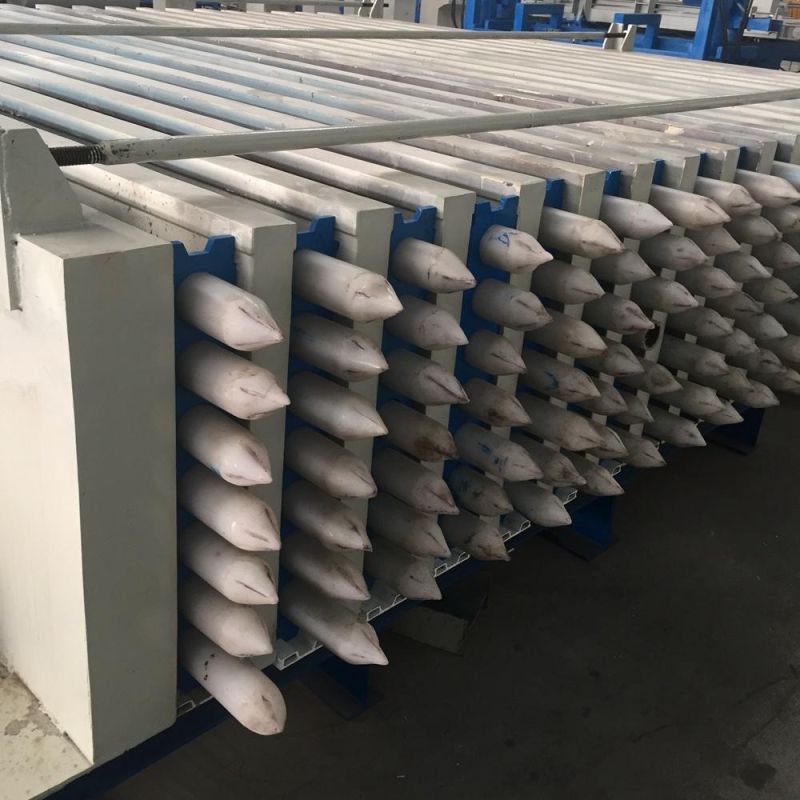

EPS sandwich panel machine line is in order to adapt to recent development trend of building materials, our company bold innovation design of highly automated production lines, which enables the waste water and materials be reused through elaborate design.This is our unique design, can full automatically demoulding, 20panels/time. So can save a lot of your labor cost .

Machinery Parameters

| Capacity | 20,000sqm~600,000sqm per year |

| Thickness | 50-250mm thickness. special sizes need to be customized |

| Length | 2440~3600mm, special sizes need to be customized |

| Width | 610mm , special sizes need to be customized |

| Raw materia | There are mainly two different types 1. Cement+fly ash/eps/ceramsite/sand, etc (optional, can choose to add or not add) 2. Fomed cement+additives |

| Finished board type | 1. Composite board/sandwich board, with surface board 2. Lightweight solid panel, without furface board |

| Surface board types | 1. Calcium silicate board 2. Fiber cement board 3. Mgo board |

| Electrical components | There are mainly two different types |

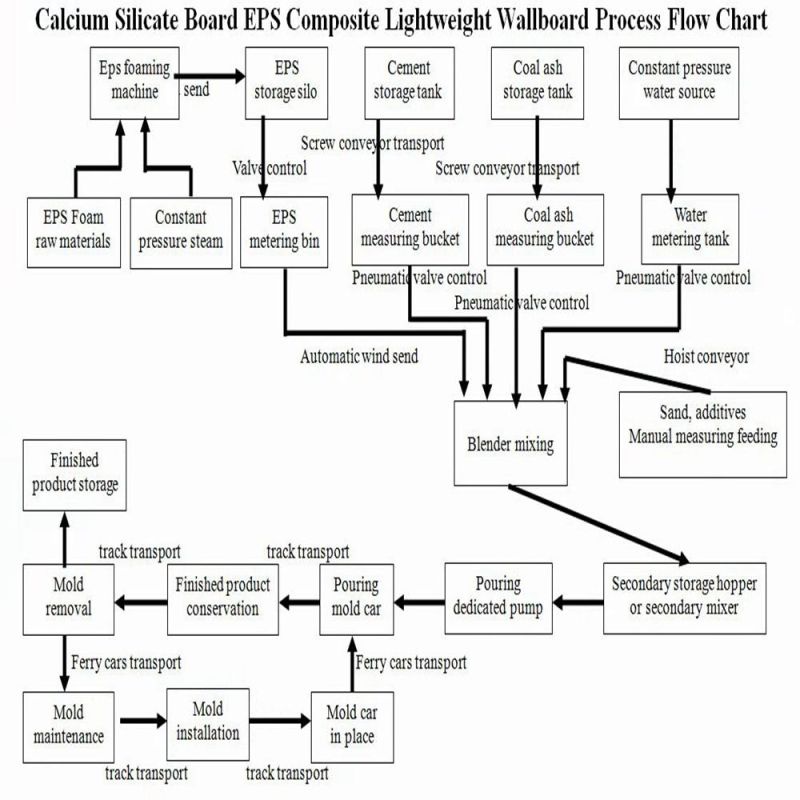

Flow chart of lightweight eps automatic sandwich panel making machine

Main Features:

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

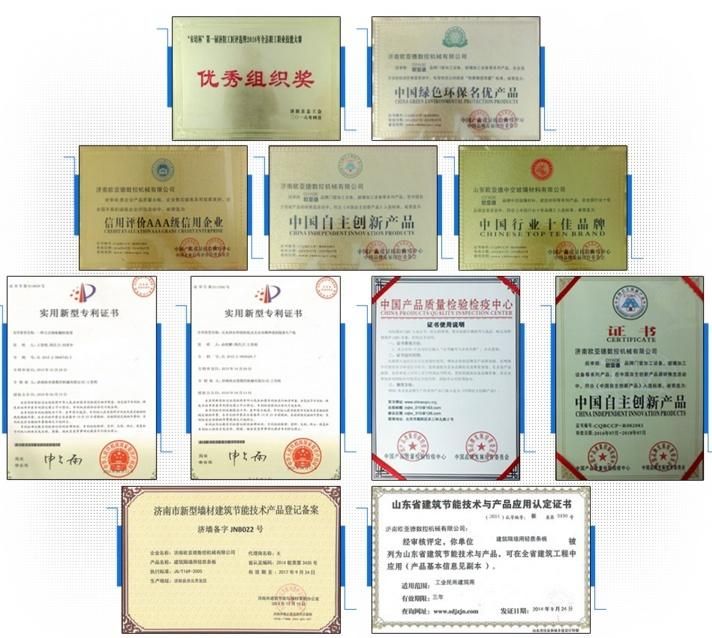

Certifications

We have over 10 patented technology in our country.Would love to show to you when you come.

Sample Project

FAQ

| 1 | Question:How many projects have you installed? Reply: we have installed over 100projects in domestic and abroad. |

| 2 | Question:How many years experience do you have in this field? Reply: Our general engineer has around 20years experience; all others have over 10years experience. |

| 3 | Question:How will you provide installation&commissioning? Reply: Will provide 2~4persons(adjustable according to configuration )for installation and testing. |

Finished Products

OUR FACTORY

Products

Jinan Oyade CNC Machinery Co., Ltd. is specialized in designing and manufacturing lightweight wall panel production forming machine. With rich experience in mechanical design and manufacturing, professional import and export services, we commitment to provide the best integrated solutions of production line for customers.

Experience

Our general engineer has over 20years experience in mechanical industry, proficient in the newest machinery design/manufacturing. Other main engineers all have over 10years experience .With rich experience in mechanical design and manufacturing, professional import and export services, we commitment to provide the best integrated solutions of production line for customers.

Promise

After installation and commissioning, we will provide technical formula suitable with client's demand, ensuring clients can produce qualified finished products. Additionally, we will help local experienced engineers for one year to master the production process.Our professional sales team, designing team, manufacturing team, installation team, process team, service team, promises you a 100% perfect project.