Roller up Shutter Door Roll Forming Machine for Sale

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, ISO, Roll up Door Roll Forming Machine

- Condition:New

Base Info

- Model NO.:Shutter Door Roll Forming Machine

- Customized:Customized

- Usage:Roof, Wall, Floor, Roll up Door Roll Forming Machine

- Transmission Method:Machinery

- Product Name:Shutter Door Roll Forming Machine

- Method:Hydraulic Pressure

- Tolerance:0.5mm

- Brick Raw Material:Color Steel

- Processing:Cold Roll Forming

- Product:Color Steel Sheet

- Color:Blue

- Machine Name:Keel Molding Equipment

- Roller Material:High Grade 45# Steel

- Type:Shutter Door Roll Forming Machine

- Transport Package:Covered with Plastic Film

- Specification:CE, SGS

- Trademark:DIXIN

- Origin:Botou, Hebei, China

- HS Code:845522

- Production Capacity:30 Sets,Month

Description

Basic Info.

Model NO. Shutter Door Roll Forming Machine Customized Customized Usage Roof, Wall, Floor, Roll up Door Roll Forming Machine Transmission Method Machinery Product Name Shutter Door Roll Forming Machine Method Hydraulic Pressure Tolerance 0.5mm Brick Raw Material Color Steel Processing Cold Roll Forming Product Color Steel Sheet Color Blue Machine Name Keel Molding Equipment Roller Material High Grade 45# Steel Type Shutter Door Roll Forming Machine Transport Package Covered with Plastic Film Specification CE, SGS Trademark DIXIN Origin Botou, Hebei, China HS Code 845522 Production Capacity 30 Sets/MonthProduct Description

Roller up Shutter Door Roll Forming Machine for Sale1.Roll forming machien components:Man-made decoiler---Color steel coil feeding & guiding device---Main forming machine---Computer Control system---Hydraulic pump station---Cutting head---Output table

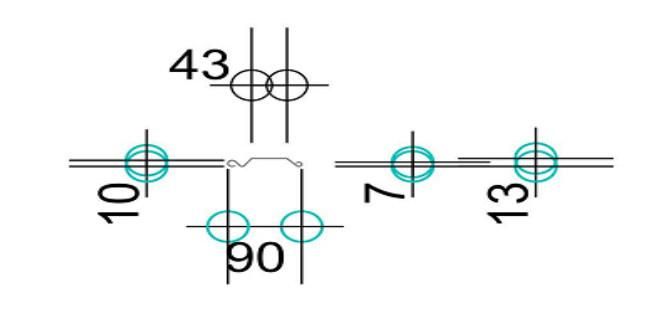

2..Technique parameters

(1) Processing material: aluzinc/galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.8mm

(3) Effective width: as drawing

(4) Feeding width:as drawing

(5) Main motor power:4kw

(6) Pump power: 4kw

(7) Shaft diameter: 55mm

(8) Forming steps: 13 steps

(9) Roller material: 45# forged steel, with hard chrome plating

(10) Main frame: square tube welding frame

(11) Medium plate thickness: 16mm

(12) Control systerm:Delta PLC computer control with touch screen

(13) Cutting blade material:Cr12

(14) Speed: 10-12m/min

(15) Drived by Chain:1inch

(16) Machine size (mm):5500*900*1200mm

(17) Machine weight:about 1.8Ton

3.Some machine pictures for your reference.

Application:Color steel sheet which are produced by our roll forming machine are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands, ancient architectures and modern villas. With advantages of long life time, stable performance and high efficiency, it is warmly welcomed by our customers. Our service:1. We provide 1 year warranty for our customers.2. Any parts damaged because of quality problem will be changed for free within the first year.3. Technical support is provided for free in the whole life of the machine.

DIXIN have a professional design team, can manufacture machine exactly according to customer's requirement.Recently, our roll forming machine have been exported to more than 40 countries and regions over the world.And maintained good cooperate relationship with customers. To ensure the production of top quality precision gears, our manufacturing techniques are upgrated constantly. If you need our roll forming machine, pls don't hesitate to contact me. We can design according to your requirements. Looking forward to cooperate with you sincerely!

DIXIN have a professional design team, can manufacture machine exactly according to customer's requirement.Recently, our roll forming machine have been exported to more than 40 countries and regions over the world.And maintained good cooperate relationship with customers. To ensure the production of top quality precision gears, our manufacturing techniques are upgrated constantly. If you need our roll forming machine, pls don't hesitate to contact me. We can design according to your requirements. Looking forward to cooperate with you sincerely!

Packing and shipping details

a. Need one 20 or 40 ft container, according to your final drawing.

b. The main body of machine is fixed to container by 8mm diameter steel wire, rollers and shaft is

covered with anti-rust oil.

c. Spare parts in carton box.

1. what is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

If you are interested in roll forming machine,please feel free to contact me directly: