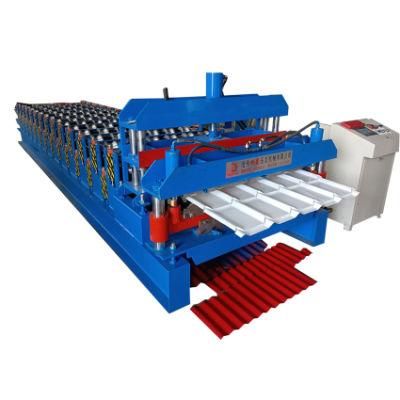

Trapezoidal Sheet Roll Forming Machine/Double Layer Roll Forming Machine Rollformers

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, ISO

- Condition:New

Base Info

- Model NO.:double layer machine

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Hydraulic Pressure

- Transport Package:Nude in Container

- Specification:7500*1500*1600mm

- Trademark:DIXIN

- Origin:Botou, Hebei, China

- HS Code:84552210

- Production Capacity:30 Sets,Month

Description

Basic Info.

Model NO. double layer machine Customized Customized Usage Roof, Wall Transmission Method Hydraulic Pressure Transport Package Nude in Container Specification 7500*1500*1600mm Trademark DIXIN Origin Botou, Hebei, China HS Code 84552210 Production Capacity 30 Sets/MonthProduct Description

Trapezoidal sheet roll forming machine/Double Layer Roll Forming Machine rollformersWidely Use

Our products are widely used in various fields: industrial factory, civilian building, warehouse, easy steel building, manufacturing, construction and have features such as nice appearance and durable.

The colored steel tiles produced by this machine look beautiful ,elegant and noble.They are widely used as the roof of garden,factory,hotel,exhibition center and villa,etc.

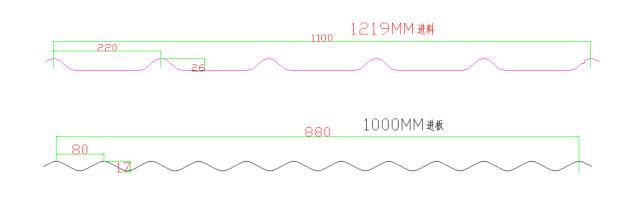

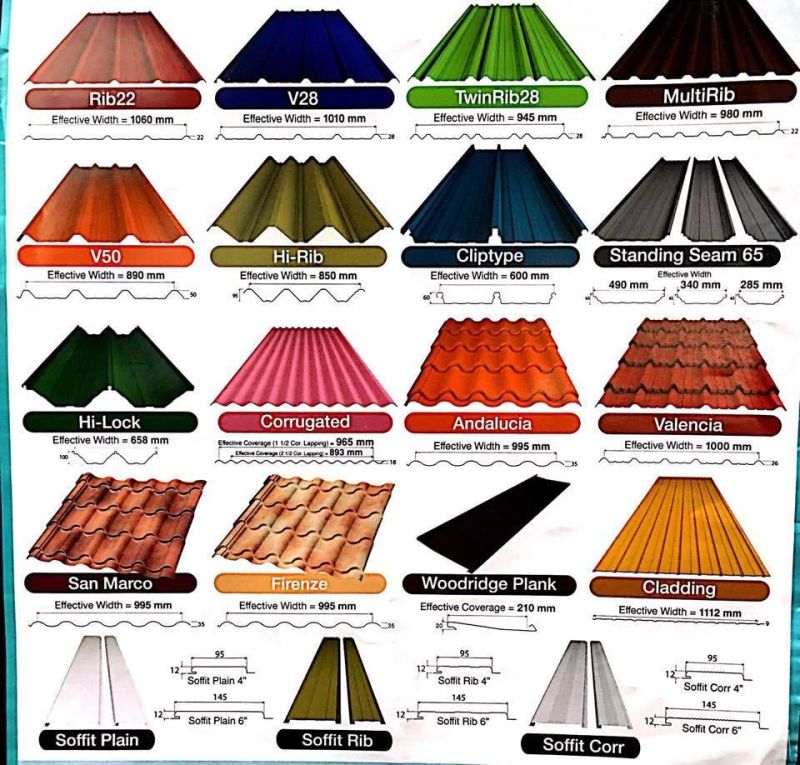

1.Panel drawing according to your design

2.Equipment detailed parameters:

| Production Name | Bangladesh Metal Roofing Sheet Double Layer Roll Forming Machine |

| De-Coiler | Manual Operation, Passively De-coiling |

| Loading of De-Coiler | 5 T |

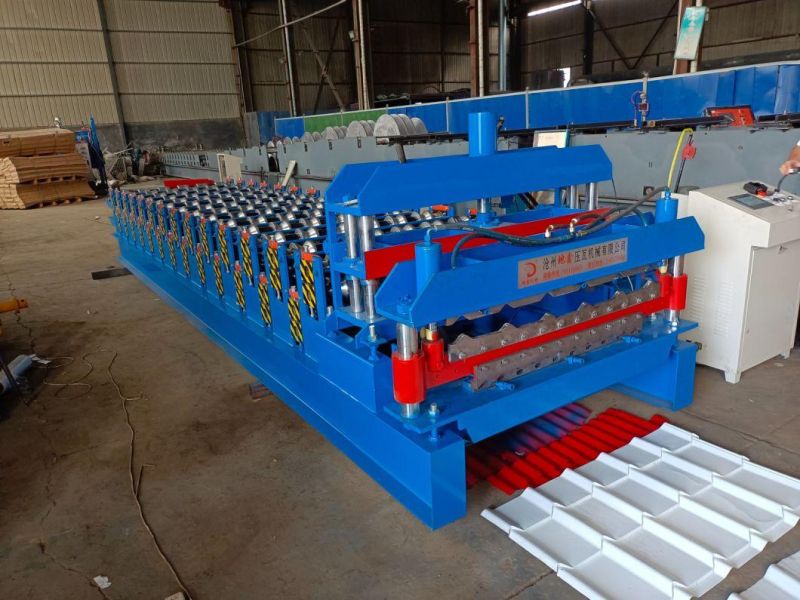

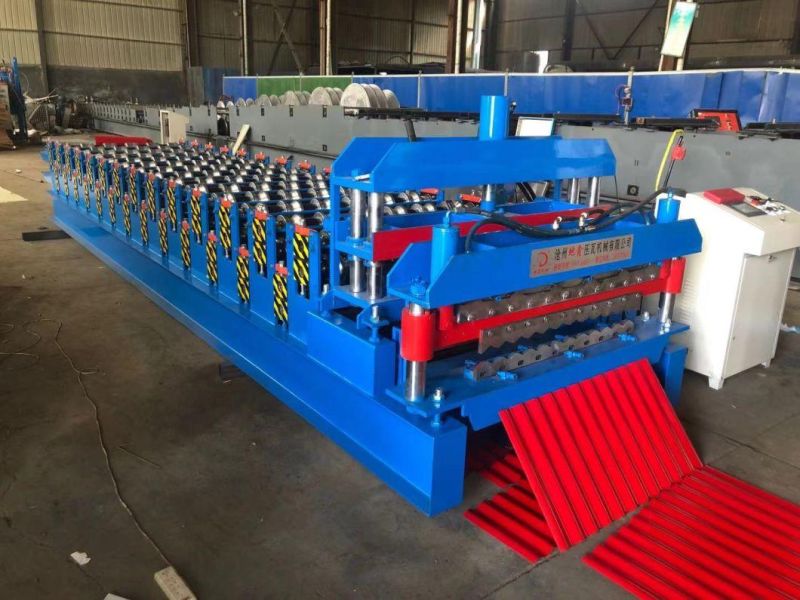

| Frame of Machine | Welded with 300H Beam Steel |

| Thickness of Wallboard | 16mm |

| Guide Feeding Way of Forming | Side Direction Roller Type |

| Forming Machine Type | Wallboard and Chain Drive |

| Diameter of Shaft | ¢75mm |

| Chain | 12A Single Row |

| Motor Power of Forming Machine | 5.5kw |

| Line Speed of Forming Machine | 12m/min |

| Steps of Forming Machine | 13steps |

| Roller Material | Superior 45# Steel Forging |

| Thickness of Chrome Plated | 0.05mm |

| Hydraulic Station Motor | 4KW |

| Hydraulic Station Oil Pump | Gear Pump |

| Cutting Way | Hydraulic Cutting |

| Cutting Blade Material | Cr12 |

| Cutting Blade Heat Treatment | HRC58º-60 |

| Rolling Thickness | 0.3-0.8 mm |

| Feeding Width | 1000mm |

| Frequency Changer | Tricrystal |

| Computer Adopts PLC | Panasonic, Computer Operation Panel Adopts Touch Screen |

| Voltage | 380V/50HZ/3 Phase |

| No. | Name | Amount |

| 1 | Passive de-coiler | 1 |

| 2 | Roll forming machine | 1 |

| 3 | Hydraulic cutting blade | 1 Set |

| 4 | Hydraulic station | 1 |

| 5 | Computer control counter | 1 |

| 6 | Run out table | 3 |

4.Packing and shipping details

1. Machines need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

5.Company information

Cangzhou Dixin Roll Forming Machine Co.,ltd is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. We specialize in the automated production line of sheet cold roll forming machines. We are able to provide an integral resolution schema of cold roll forming system through a combination of advanced system design and equipment. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely.

6.Some others samples

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,shutter door machine, floor decking machine and other associated equipment.

Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

7.Contact way

If you want to know more information about Hydraulic Automatic Color Roof/ Wall Steel Sheet Forming Machine with European Standard in Botou City, please contact to me now.