-

Colour Coated Roofing Sheet Making Machine

Product NameColour Coated Roofing Sheet Making MachineBrandHXTypeHX840+HX900Colour Coated Roofing Sheet Making MachineBase materialGI. GL.PPGI. PPGL .Aluminum Thickness0.3mm-0.8mmEffective Width840mm+900mmSize5000*1500*1600mmWeight4.5TonsFrame Material350H SteelSide Panel Of Machine16mmRows13+15 ro

-

Good Price Metal Steel Roofing Corrugated Sheet Roll Forming Machine

Overview After Sales ServicePackaging &ShippingCompany ProfileExhibition &Client VisitFAQ.How to play order :Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit ---we start producingWhat can we do if the machine broken?The machine will b

-

Door Frame Press Steel Door Roll Forming Machine with Best Quality

Overview After Sales ServicePackaging &ShippingCompany ProfileExhibition &Client VisitFAQ.How to play order :Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit ---we start producingWhat can we do if the machine broken?The machine will b

-

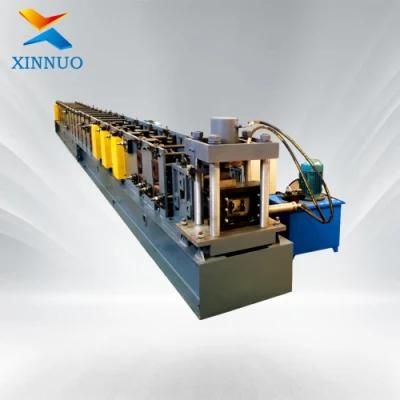

Xinnuo Storage Rack Roll Forming Machine

Overview Product DescriptionDetailed PhotosOur AdvantagesPackaging & ShippingCompany Profile

-

V-Type Wire Mesh Wrapping Machine

Overview Detailed PhotosPackaging & Shipping1---Inner packaging: the main machine is naked, but the important parts like electrical part arewrapped by stretch film.2---In the container, the machine will be tighenedby steel wire ropes3---1*40GP is enough, and spare parts and si

-

Gear/Sprocket, Gear Box, Toroidal Worm Box Purlin Roll Forming Decorative Panel Machine

Product Rack3 units, un-powered

-

Ridge Cap Colour Coated Tile Roll Forming Machine

Overview After Sales ServicePackaging &ShippingCompany ProfileExhibition &Client VisitSales NetworkFAQ.How to play order :Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit ---we start producingWhat can we do if the machine broken?The m

-

Overview Product ParametersProduct DescriptionDetailed PhotosCertificationsPackaging & ShippingCompany ProfileGEIT GROUP is a professional manufacturer and exporter which is concerned with the design, development and production of cold roll forming machines.The factory located

-

Overview Product ParametersProduct DescriptionDetailed PhotosPackaging & ShippingCompany ProfileGEIT GROUP is a professional manufacturer and exporter which is concerned with the design, development and production of cold roll forming machines.The factory located in Botou-Hebe

-

Double Corrugated Automatic Roof Panel Tile Price Roll Forming Machine

Basic Info. Model NO. Customized